Cemented Carbide blades and Tools for Woodworking

Cemented Carbide Tooling for Woodworking

The right choice for every applicationAre you an expert in woodworking? Cemented carbide is a popular material for processing a wide range of wood and wood construction materials. High cutting speeds and long service life are two convincing arguments for using our carbides.

SPP CARBIDE is your contact person for hard metal products. Our product range offers you solutions for all areas of application.

Cemented Carbide Drilling Components(Drill bits and nozzles)

Tungsten Carbide Compacts for Oil, Gas, Seismic, Mining, Water Well & Geothermal Drilling;

Drill Bit Inserts, Buttons, Grips, Drag Bit Profiles, Gage Blocks, Nozzles, Chips etc。In the relentless search for new sources of energy, whether hydrocarbon-based or carbon-free geothermal, advanced drilling technology makes possible their discovery and utilization. High performance SPP tungsten carbide inserts, buttons, gage blocks and drag bit profiles are hard at work every day in drill bits around the world probing the earth's crust for oil, natural gas, geothermal energy, in seismic drilling, in mining exploration and production and drilling water wells for homes and communities.

SPP CARBIDE offers a full range of sintered tungsten carbide drill bit components for hard and soft formation drilling and boring equipment.

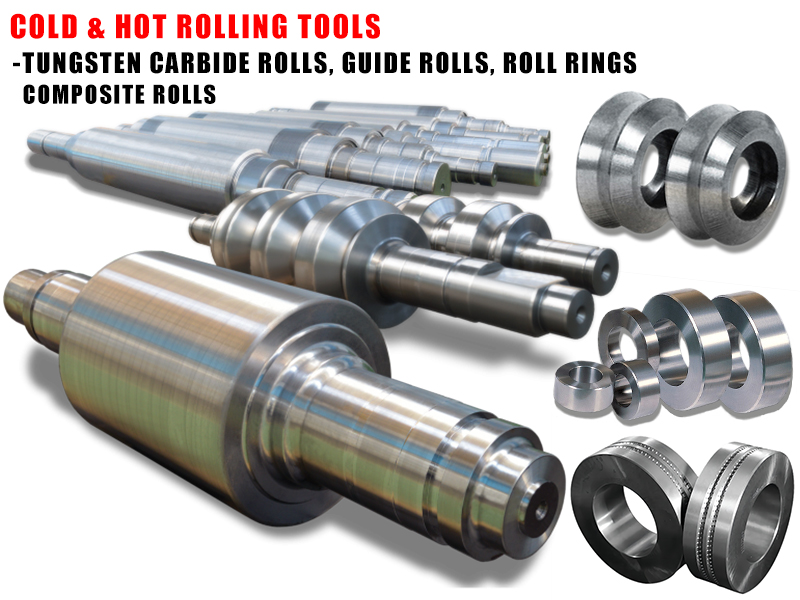

Cemented Carbide Tools for Hot Rolling

Cemented Carbide Tools for Hot Rolling - SPP CARBIDE Manufacturer

The company has 30 years of experience in the manufacture of hot and cold rolling replacement parts, supplying tungsten carbide, carbide, technical ceramics, hardened steel replacement parts and tooling to renowned Chinese and European steel, wire rod and tube manufacturers.

Typical Products:

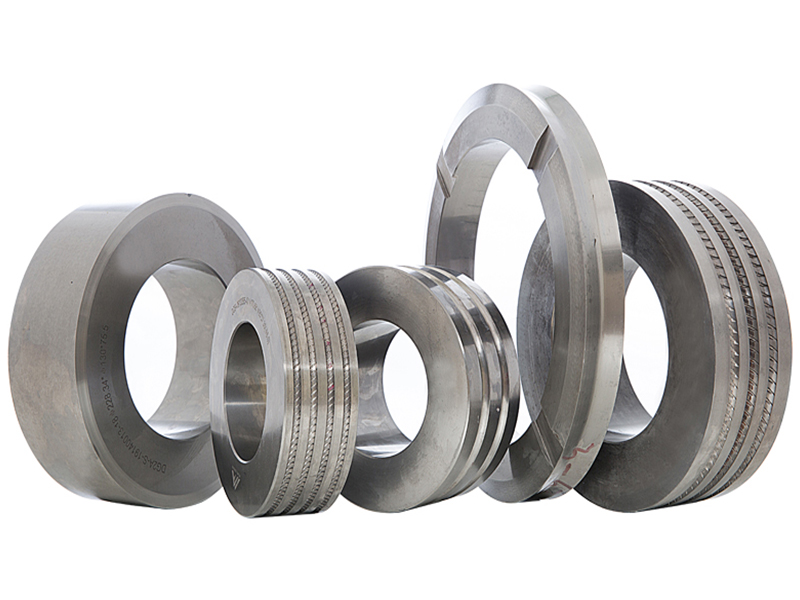

Rod and Coil Rolling Mill Rolls Rings

Tungsten Carbide Rolls

Wire Guide Wheels

Torsion Rolls

Tilt Rollers

Cooling Nozzles

Inlet and outlet wire guides

Cemented Carbide Compoite Roll

Three Carbide Rings

HSS Rolls, etc.Cemented Carbide Valve Balls

Ball

As the core component of the ball valve, the ball plays a decisive role in the quality and stability of the ball valve and its service life, our company has been supplying ball products for more than ten years to ball valve manufacturers, and the stable quality has been widely praised.Technical parameters:

Specification: diameter 1/4″~8″

Structure: L-type, T-type, V-type, X-type, hollow sphere, etc.

Pressure: Class150-900

Base material: tungsten carbide, technical ceramics, A105, F304, F316, F316L, etc.

Surface treatment: Electroless nickel plating (ENP), tungsten carbide (TCC), Stearic carbide (STL), Inconel, etc.

In addition to standard parts we also manufacture valve balls according to customer drawings.Cemented Carbide Wear Parts & Tooling manufacturers

Carbide wear parts are adapted to a variety of high strength, high wear resistance working conditions, the company customised carbide tools according to customer drawings.

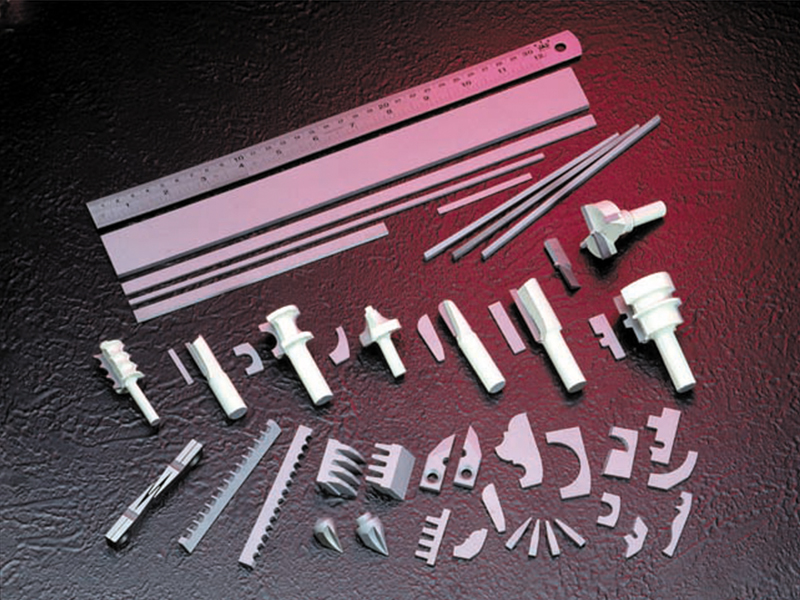

Cemented carbide has high finish, high hardness and high brittleness, so whatever your requirements, the company can sinter the appropriate carbide grade.Cold And Hot Forging Tools & Cutting Knives

Cold And Hot Forging Tooling

Tools in this category can be:

Cutting knives

Cutting dies

Pre shapers / Pre compressors

Final shapers

Shapers

Compacting dies

Forging dies

Conic dies

Reducer dies

Steel & Hard Metal Tools:

Drawing Dies

Drawing Mandrels

Cold And Hot Forging Tools

Rolling Tools

Special Hard Metal ToolsCutting and trimming dies

Stamping dies

Cold heading dies

Reduction / extrusion dies

PunchesCold and Hot Rolling Tools-Tungsten Carbide Rolls

SPP CNC MACHINING has been researching, developing and producing tungsten carbide rolls and HSS rolls since 1994. We have patents for a number of products such as tungsten carbide rolls, casting rolls, HSS rolls, roll rings, composite rolls, guides, inserts, wide-band work rolls, forged steel rolls, arbor rods and drums, and mill rolls. We mainly serve with the fields of steel manufacturing, wire rod manufacturing, pipe manufacturing, cold rolling and hot rolling technology, mill manufacturing, etc.

Cold Forming Tooling and Cold Forging Die

Cold Heading Tooling includes:

Carbide and Steel Inserts

Extruding Dies

Taptite ® Inserts

Torx ® and Torx Plus ® inserts

Strux ® Tooling

Magform ® Tooling

Die Cases and Punch Cases

Sleeves

Trim Dies

Cut Off Knives

Quills

Nut Forming Tooling

Knock out pins

Punches

Steel and Carbide Extrusion Pins

Feed Rolls

Prototypes

Machine Parts

Wear Coatings

Carbide DIES

Carbide PVD coated punches

Shaping Dies

Tungsten Carbide Inserts

Taptite

Taptite 2000

T Tap

Torx

Torx Plus

RemincCold Heading Tooling And Cold Forming Tooling

For 50 years, SPP CARBIDE has earned a reputation for producing the highest quality cold heading dies and cold forming dies as well as reliable service and providing the best value for our customers.

We are able to achieve this because of the experience of our talented machinists and because we use state-of-the-art 2-5 axis multi-axis lathes and milling machines in our in-house grinding department and automation in areas such as our wire cutting and stamping EDM departments to produce tools and parts to tight tolerances at competitive prices.

Custom Machining Agricultural Carbide Tooling and Parts

SPP Industry has the experience and knowledge to customize ground tillage tools, plows and other agricultural machinery manufacturing parts to your specific geometry.

Depending on your application, we can help design and recommend the best grade of carbide to help your equipment consistently deliver the best performance.Custom Machining Ammunition & Firearms Tooling Carbide Dies

We manufacture tungsten carbide tooling and dies for ammunition and gun tooling, Draw Dies, Profiles, Underfire stamping dies, Bullet Dies, Punches, Forged Tooling, AP Cores, Cartridge Drawing Die etc.

SPP INDUSTRY aims to produce the highest quality tooling for the manufacture of ammunition tools, combining the new carbide and hardened steel steels. A high precision CNC grinding centre for the machining of correctly shaped tip shapes with a mirror polished finish replaces the traditional hand polishing process.

Grinding and polishing of the internal contours of all construction matrices is performed only once, with perfect tangency between cone and radius.Custom Machining MWD, LWD & FE Wear Parts

MWD, LWD & FE Components

We provide gundrilling solutions necessary to support today's, and tomorrow's leading edge Formation Evaluation, Rotary Steerable, Well Completion and reservoir management technologies.M.W.D. COMPONENTS AND L.W.D TOOLING.

Mud Deflectors

Valve Seats and Stems

Rotors and Stators

Erosion Sleeves

Flow Restrictor Bearings

Main Pulser Components

Orifices

Solid Carbide or Two- Piece Threaded Nozzles

Seal Rings

Ported Flow Cages

Thrust Bearings