Carbide Cutting Tools

Carbide Cutting Tools

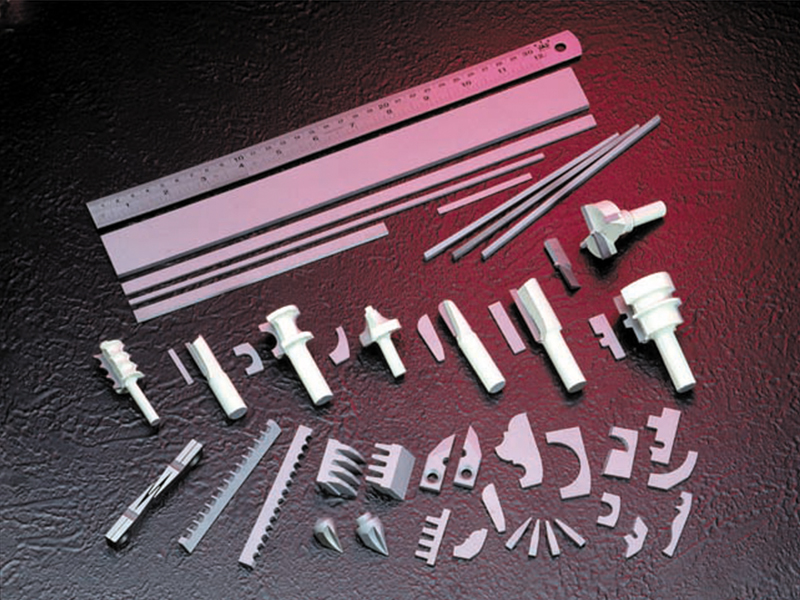

We are specialized in designing and manufacturing high-efficiency tungsten cutting tools. We have advanced machines from brand:ROLLOMATIC,WALTER,MAKINO SEIKI AND VOLLMER. The raw material are from Taiwan CB carbide,SUMITOMO from Japan or Guhring from Germany,and available for Bakzers、PVD coating. The unique design and strict quality management have provides strong guarantee for high-quality, high-efficient and more stable new products.Carbide Cutting Tools for the Paper Industry

Paper converting industry

From paper to cardboard to special cellulose products such as tissue or other items in the hygiene industry, carbide ensures significant results and higher productivity. Compared to tempered tool steels, cemented carbide offers higher pressure and wear resistance. It improves cutting edge stability and thus provides better dimensional accuracy. cutting tools made of SPP carbide achieve excellent cutting results - perfect cutting.

Carbide Special Inserts

SPP CARBIDE specialises in the manufacture of standard carbide inserts and special carbide inserts. All products are manufactured using the latest PVD and CVD coating technology. This wide range of grades allows us to "fine tune" a particular grade to your specific operating needs. We thrive on tight tolerances.

We offer ANSI and ISO standards combined with the industry's tightest tolerance grinding to maximise tool life and reduce cycle times. Add our precision regrinding and/or size reduction programs for the most effective manufacturing cost reduction.

Our carbide insert materials, whether coated or uncoated, are known to perform as well or better than our competitors. We provide not only the manufacture of inserts but also the carbide powder metallurgy tooling for insert manufacture and we are often in competition with other major manufacturers. It is part of our daily routine to cross over directly to our competitors' results and recommend better results.

Carbide Special Tools and Inserts Manufacturer

We are Manufacturer, Supplier, Exporter, Services of Solid Carbide Tools, Counter Bores, Countersinks, Form Cutters, Corner Radious Cutters, Woodruff Cutters, Boring Tools and our setup is situated in Dongguan,Guangdang,China.

We offer manufacturing and OEM services for solid carbide tools and inserts, including:

Counter Bores

Countersinks

Form Cutters

Boring Tools

Woodruff Cutters

Corner Radius CutterCarbide Cutting Tools

Tungsten Carbide Cutting Tools

Brazed carbide and HSS tools etc.Cemented Carbide blades and Tools for Woodworking

Cemented Carbide Tooling for Woodworking

The right choice for every applicationAre you an expert in woodworking? Cemented carbide is a popular material for processing a wide range of wood and wood construction materials. High cutting speeds and long service life are two convincing arguments for using our carbides.

SPP CARBIDE is your contact person for hard metal products. Our product range offers you solutions for all areas of application.

Custom Machining Agricultural Carbide Tooling and Parts

SPP Industry has the experience and knowledge to customize ground tillage tools, plows and other agricultural machinery manufacturing parts to your specific geometry.

Depending on your application, we can help design and recommend the best grade of carbide to help your equipment consistently deliver the best performance.Slitting Machine Blade

Custom Industrial Slitter Knives

Slitter knives are designed to slit a variety of materials in a variety of applications. Because of their ability to cut materials such as paper, plastics and textiles, they are used in many industries. At SPP CARBIDE, we sell both straight and rotary blades. We can design blades for a variety of machine models and customize each result for our customers. If you need a knife for slitting applications, the SPP CARBIDE team will work with you to find a slitting knife solution that meets your needs.Most slitting blades feature a beveled edge for optimal cutting power. The beveled edge allows the blade to cut through the material rather than making a standard cut. When the primary purpose of a slitter knife is to make a puncture, it has teeth. These teeth gradually create smaller slits, such as those found on tear-off paper products. Our sales engineers can help you determine which blade solution is best for your application.

At SPP CARBIDE, all of our slitting blades are manufactured in-house. As an original equipment manufacturer, you'll appreciate our competitive pricing and fast turnaround times that maximize your profits. If you get our blades as an end user, we will listen to your needs to design a customized solution. We view your business goals as our business goals.

Tooling and Dies for CNC Special Insert Manufacturing

SPP CARBIDE offers carbide tooling manufacturing services for CNC cutting inserts and tools. Special CNC cutting inserts and tools are manufactured from carbide powder metallurgy and we offer manufacturing of carbide powder metallurgy tooling with a special tungsten carbide liner and a housing made from tool steel.

Products include:

3R tooling

Finished tooling

CNC insert tooling

Magnetic core material dies

Tungsten Carbide Ring Dies

Tungsten Carbide Bar Mould

Tungsten Carbide Ball Mould

Tungsten Carbide Block Mould

Tungsten Carbide Nozzle Mould

Cemented Carbide Drawing DieTungsten Carbide Circular Knives

Manufacturer of Circular Knives

We produce a wide range of knives for a variety of applications from a minimum diameter of 2mm to a maximum of 950mm and offer specific solutions for cutting any job.

We have specialised in manufacturing knives for over thirty years to cut a wide variety of materials such as cardboard boxes, plastics, rubber, cork, deep frozen goods, rubber tubes with or without metal weft yarns, paper tubes and foam. The tool material depends on the material to be cut and the productivity needs of the customer. dongguan spp industry Co.,Limited uses different steels (carbide, diamond, sapphire, ruby, HSS, hardened tool steel, martensitic stainless steel SUS630, etc.) and offers a wide range of solutions for all applications.The tool shape is very important; the standard shape for common applications is defined by a sharpening type that can be single or double bevelled. Round knives are usually as sharp as straight knives and can have or not have teeth depending on the material being cut. Technological advances in blade geometry and the experience we have gained in several applications have shown that for certain materials a specific tooth shape or a specific kerf significantly improves cutting performance. We usually design and produce tools for specific customers.