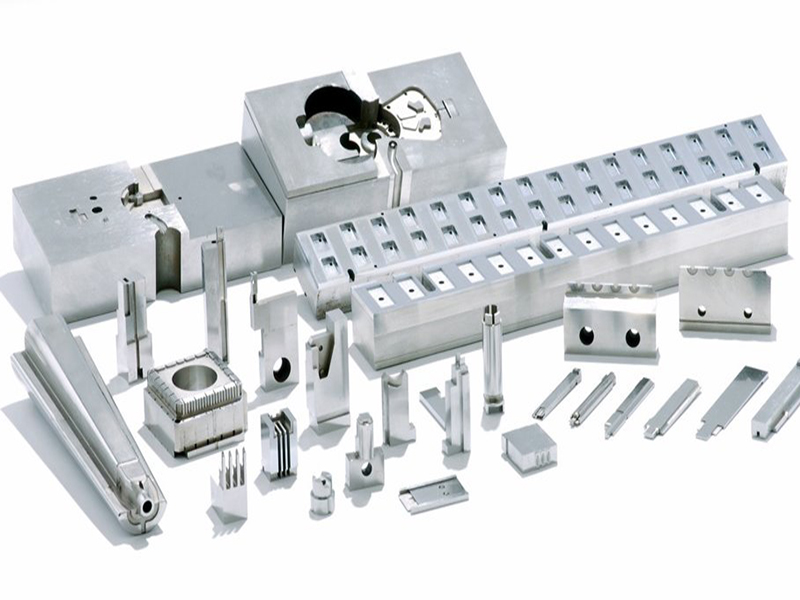

Array of Shaped Die Components for Optical Lenses

The company is a specialist manufacturer of optical tools and optical moulded components and we offer CNC high speed 5 axis milling, micro machining and fine hole EDM services.

Optical components generally require a very tight polish and we can perform precision mirror polishing of curved or straight lines to a surface Ra 0.01um.

Auto Mold & Chase and Conversion Kit

Automold Chase

-All kinds of automold chases

-All kinds of full conversion kits for auto mold system

-Solution for venting and gating design to ensure good moldability performance (Void, Wire Sweep and incomplete filling)

-Standard Cavity Bar Material : ASP23

-Convertible Mold Die for other package type

-Minimized compound usage Automold Conversion Kits

-All kinds of full conversion kits for auto molding system

Automotive Lens & Mirror Forming Die Tooling and Parts

The company has 16 years of experience in the manufacture of moulded components for automotive lenses and lens moulding. We manufacture moulded components and tools for optical components, which consist of tungsten carbide or hardened tool steel with a rigorous mirror finish.

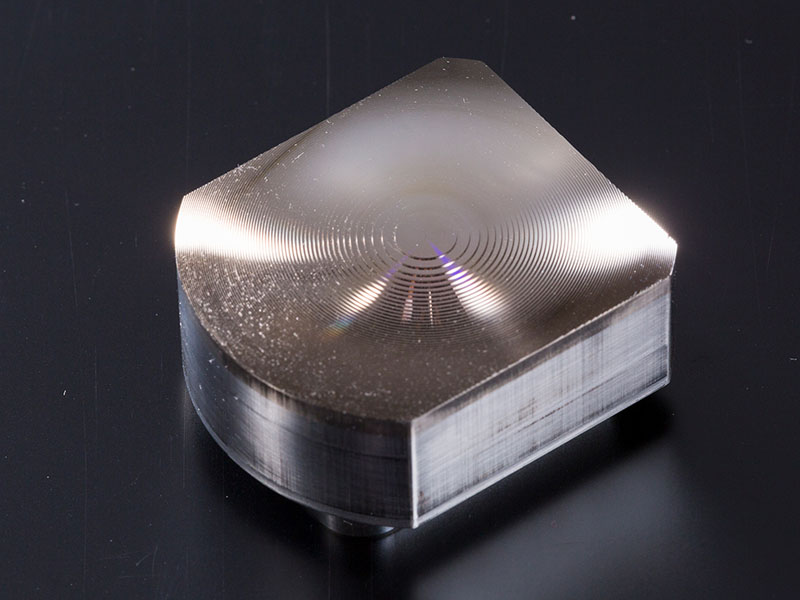

Car Profile Light Mould(Groove Surface roughness Ra0.04µm)

The company specialises in moulding tools for automotive optics and offers a high precision OEM component manufacturing service for automotive contour lamp moulds, we can perform mirror polishing services on contours and achieve Ra0.01um

Custom Machining Pot & Plunger for Semiconductor Packaging

The company is one of the largest manufacturers of Pot & Plunger in China and we provide OEM services for Pot & Plunger to well-known semiconductor companies in China and Taiwan.

Pot & Plunger is used in the manufacture of semiconductor packaging moulds. The company's Pot & Plunger can be manufactured using M42 high speed steel or tungsten carbide and can also be supplied with additional PVD coating services.Die Inserts for Precision Equipment and Optical Components

The company has been specialising in the manufacture of moulded components for 26 years and we are one of the leading brands in the manufacture of moulding tools for the moulding of optical components.

The company uses globally advanced equipment to manufacture mould components, mould cores, mould inserts, mould cavities, mould slides, mould core pins and more.

Fresnel Lenses Machining for Optical Tooling Components

Advantages of Precision Machined and Custom Fresnel Lenses and Fresnel Lenses.

Physically, the Fresnel lens has a narrow profile that focuses light similar to a conventional optical lens, but has several advantages over its thicker counterparts:

Light weight: a very interesting option in situations where weight is important (automotive, aerospace, etc.);

Large format: Fresnel lenses are very useful for standard and wide-angle applications;

Various substrate materials: substrate materials vary from acrylic to polycarbonate and glass.

Performance: excellent light gathering capability.Glass Lens Tooling Forming Moulds and Die Kernels

We are a manufacturer of moulds for the forming of optical components (lenses). Optical lens moulds generally require a very rigorous mirror polishing of the die insert, cavities, cores and inserts.

We support high precision mirror polishing services, not only on carbide materials but also on stainless steel, tool steel and aluminium alloys.

IC Packaging Mold Cavity Bar and Auto Mold Chase

Application: Suitable for TOWA, FICO, ASM, HANMI brand AUTO MOLD SYSTEM

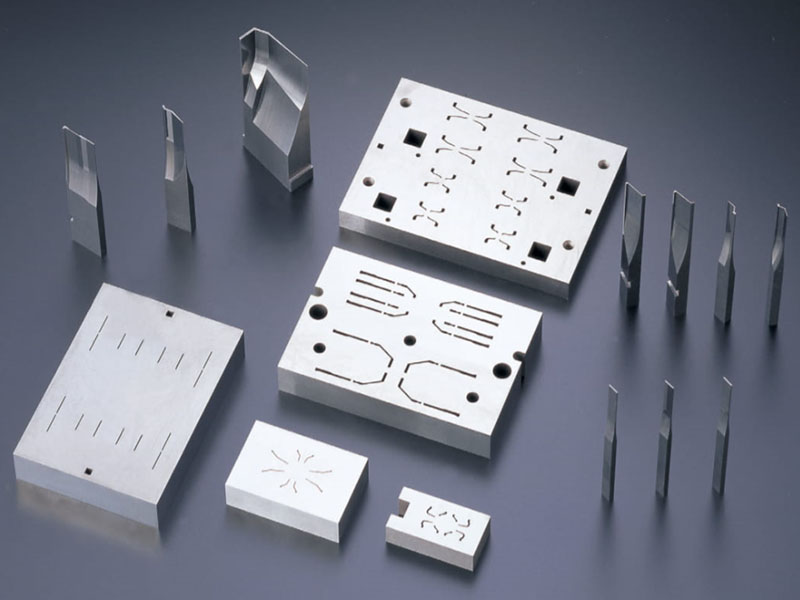

Can be used in conjunction with automatic encapsulation systems to improve the intrinsic quality of the product.Lead Frame Tooling & Stamping Die Parts

SPP INDUSTRY manufactures a variety of leadframes using ultra-precision tooling by stamping and etching, and provides OEM services for high-precision tooling components.

Mould Components for Optical Components Manufacturers

The company is very well positioned in the field of moulding tool manufacture for optical components and has become a well-known Chinese manufacturer of optical components and a gold supplier in the field of research.

We supply mould components for the forming of optical components including, cores and inserts, slides and die kernels, cavities and cavities, templates and overlay components, punches and matrices.OEM/ODM Punches and IC Die Pins for Semiconductors

Precision stamping die components are used in the semiconductor field. Punches and IC die pins are finished with tungsten carbide or hardened tool steel, and additional PVD coating services are also available. SPP INDUSTRY's die components are 6 times more durable than ordinary die standard parts, which is one of our patented products.

的模具.jpg)