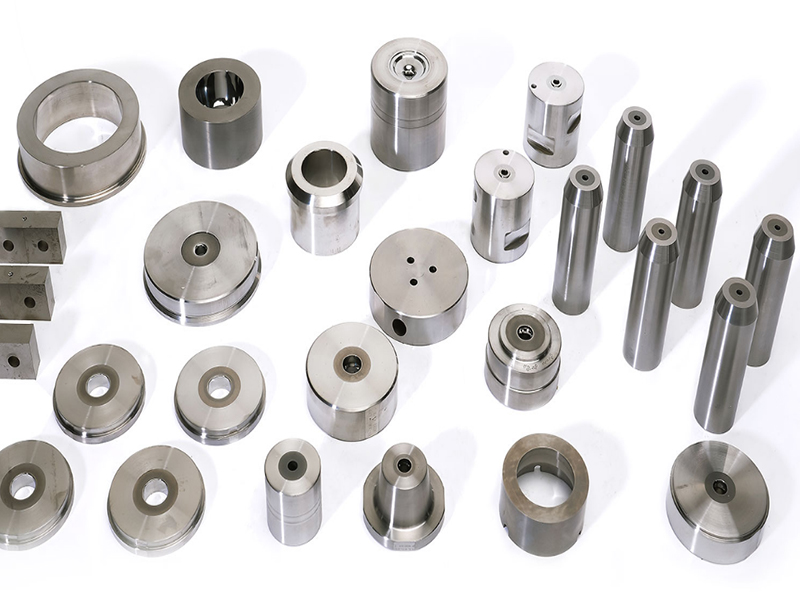

Automotive Tungsten Carbide Custom Tooling Macining

Automotive Technology

We help keep the automotive industry alive.

New innovations, changing products and customer demands have made flexibility and adaptability part of manufacturing in the automotive industry, as has the production of tools and dies used in the automotive market. The tools and mold solutions produced need to be flexible, precise and durable to withstand the rigors of automotive manufacturing and create a significant return on investment to help you stay competitive.

SPP CARBIDE offers tool manufacturing services in a wide range of materials such as tungsten carbide, technical ceramics, steel, aluminum alloys, etc., which are perfectly suited to meet the custom tooling machining requirements of the automotive and new energy vehicle sectors.

Our part machining services and solutions are used by companies in the automotive industry for a number of custom tool and die components, including:

Steel casings

Sleeves

Filler

Backing nuts

Carbide inserts

Steel inserts

Pins

Knock outs

Punch casings

Transfer fingers

Feed wheels

Impact dies

Quills

Cut off knives

Die block holders

Crimping dies

Stamping Die Components

Guidance components

Carbide cold heading tools

Carbide hot forging tools

Tungsten carbide wear parts

Bushings

Shafts, eccentric shafts, crankshafts, camshafts, etc.

Knowledge and expertise in materials, design and best practices

SPP CARBIDE's extensive knowledge and expertise in creating custom tooling and molding solutions to meet exacting specifications quickly and accurately helps optimize the efficiency and productivity of your manufacturing program.

Our innovative tool and die technology platform and industry-recognized processes virtually eliminate the possibility of product failure. In addition, our team of expert machinists has the ability to provide creative solutions through alternative material recommendations, design changes and best practices for efficient production.

We can also recommend material choices that are relevant to a particular requirement or condition, and combined with our state-of-the-art CNC equipment, we can ensure that every drawing requirement for a tool is met to perfection.

Parts common to a variety of industries, including automotive, can be very long, but also have a small outside diameter. This type of part can be extruded deep into the die, but the diameter keeps decreasing during the extrusion phase. The wrong die for this application can lead to extrusion discrepancies and produce bent parts that are prone to failure.

Our machining specialists have the expertise in die manufacturing to produce parts that expand in length while maintaining a perfect radius on small diameters. Combine this with our ability to produce customized parts for a variety of unique applications, and our technicians will help ensure that your machine runs at peak performance.

Related products

Cold Forming Tooling and Cold Forging Die

Cold Heading Tooling includes:

Carbide and Steel Inserts

Extruding Dies

Taptite ® Inserts

Torx ® and Torx Plus ® inserts

Strux ® Tooling

Magform ® Tooling

Die Cases and Punch Cases

Sleeves

Trim Dies

Cut Off Knives

Quills

Nut Forming Tooling

Knock out pins

Punches

Steel and Carbide Extrusion Pins

Feed Rolls

Prototypes

Machine Parts

Wear Coatings

Carbide DIES

Carbide PVD coated punches

Shaping Dies

Tungsten Carbide Inserts

Taptite

Taptite 2000

T Tap

Torx

Torx Plus

RemincScrews Header Punches (Second Punch)

Screw Head Punches (Screw Second Punches), Second Head Punches manufacturers and suppliers.

Phillips punches, screw punches, slotted punches,Recess Punch, Header Punch,second punches, Header punch dies

The header punches are for various screw drives recess like phillips, slotted, phillips slotted, 6 lobe, 6 lobe tamper, 6 lobe slotted, pozi, pozi-slotted, hexagon, spanner, phillips-slot.ind, slot.ind or customized design.Head punches are available for ANSI, JIS, DIN or ISO standards for flat, oval, bundled, pan(JIS), pan(ANSI), round, truss, button, disc washers, cheese, tin TiALN screw head punches thread rolling dies, upsetting dies and fillers. It is also available in custom designs. Please provide us with your detailed specifications or screw drawings for our reference when you enquire or order.

Materials: M2, M42,HSS,Carbide,ASP23,1.3343 etc.

Finishes: plain, TiN, TiALN coated. Fastener forming tool manufacturer.Cold And Hot Forging Tools & Cutting Knives

Cold And Hot Forging Tooling

Tools in this category can be:

Cutting knives

Cutting dies

Pre shapers / Pre compressors

Final shapers

Shapers

Compacting dies

Forging dies

Conic dies

Reducer dies

Steel & Hard Metal Tools:

Drawing Dies

Drawing Mandrels

Cold And Hot Forging Tools

Rolling Tools

Special Hard Metal ToolsCutting and trimming dies

Stamping dies

Cold heading dies

Reduction / extrusion dies

PunchesSpecial Shaped Cold Forming Punches & Tooling

Cold heading extrusion punches

Cold heading is the process of feeding wire into a machine that cuts it into pieces and then hammers it. The material is not heated or processed, but formed into the desired shape at room temperature. The ability to form the material rather than remove it makes the process extremely efficient and cost effective in high volume production.We design and manufacture our own custom tooling and make virtually all fastener forms, including multiple upsetting configurations, custom head shapes and replacements for multi-part assemblies. Transforming your supply requirements to cold heading can benefit in many ways.

SPP Industry Ltd.

In the 1990s, SPP Industry Ltd was one of the first manufacturers to establish CNC machining in China. The company has now established five major machine parks in China, with significant achievements in the areas of 5-axis machining, precision grinding & honing, gear machining, large parts machining, custom tungsten carbide and new material development respectively.