Carbide Cooling Nozzles for Cold and Hot Rolling

Nozzles for roll cooling

Optimum roll cooling in hot and cold rolling mills

During the rolling process in hot and cold mills, heat is generated by mechanical deformation of the rolled parts due to frictional deformation. Effective cooling of the work rolls and support rolls (if necessary) is therefore essential for the forming process to ensure stable roll temperatures as well as efficient heat transfer and heat dissipation. Therefore, the goal is to create uniform, even cooling over the entire roll width with a homogeneous and acceptable heat distribution.

SPP CARBIDE produces cooling nozzles for hot or cold rolling mills. The use of tungsten carbide nozzles with either an integral tungsten carbide or a shell steel core allows for tens of times the failure of normal stainless steel.

Material options: tungsten carbide, high-speed steel, stainless steel, etc.

The basis for efficient and economical roll cooling is the optimal arrangement of nozzles and bars. The most important aspect of rolling is the heat generated by friction and deformation during the rolling attack.

The most important aspect is:

Ensuring consistent and stable roll temperatures around the roll and over the entire roll width

Optimum heat ball generation and minimum temperature difference between the upper and lower work rolls as well as optimum cooling

As a result of the current increase in the thickness of hot strip, there is an increasing demand for mills to roll smaller final sizes, resulting in higher pass depressions on individual mill stands. Such large thickness reductions result in larger contact areas, as well as higher rolling forces, heat generation and higher rolling forces.

These pass arrangements, coupled with the need to roll an increasing number of material cross-sections in a wider range of soft and hard materials, lead to greater challenges in controlling working rolling temperatures and effective heat removal.

Achieving uniform, homogeneous cooling

The ultimate goal is to achieve uniform, homogeneous cooling over the entire roll width. With an optimally designed roll cooling system in perfect condition, several important goals can be achieved:

Maximum heat removal with minimum coolant consumption

Symmetrical temperature distribution on the working rolls

Hot pack control

No temperature difference between upper and lower work rolls

Ensuring that the roll bending system remains in the desired working area by maintaining the height and symmetry of the heat pack.

Roll cooling nozzles for hot and cold rolling technology

Related products

Rolling Mill Rolls

Mill Rolls

SPP CNC MACHINING customised specialists for the best solution for you!SPP CNC MACHINING is a company specialising in the customisation of precision components. With years of experience and advanced production equipment, we can provide you with high quality and reliable roll products.

Our mill rolls are suitable for all kinds of metallurgical industries, including the production of bars, wires, profiles, strips, tubes and so on. We can customise the rolls according to the specific requirements and application scenarios of our customers to ensure their performance and longevity in various environments.

Material options: tungsten carbide, high speed steel, cast steel, ductile iron, tungsten carbide coating, etc.

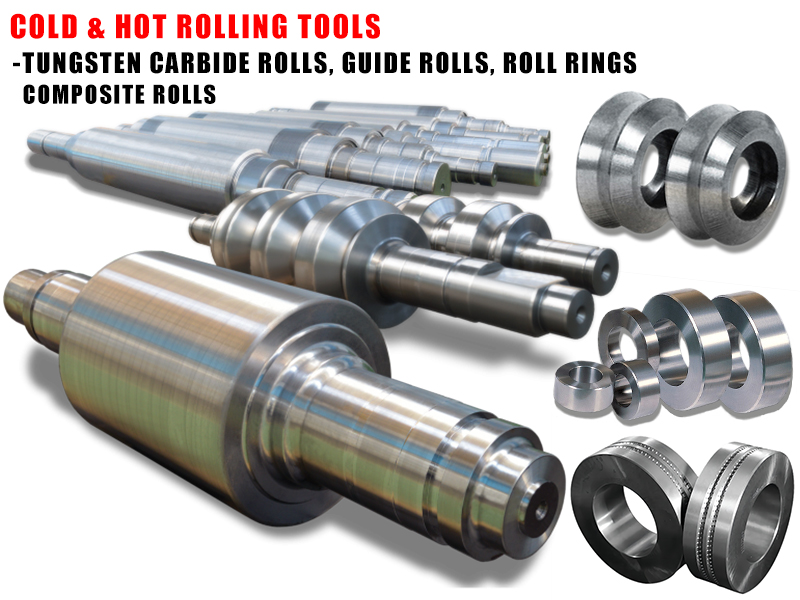

Cold and Hot Rolling Tools-Tungsten Carbide Rolls

SPP CNC MACHINING has been researching, developing and producing tungsten carbide rolls and HSS rolls since 1994. We have patents for a number of products such as tungsten carbide rolls, casting rolls, HSS rolls, roll rings, composite rolls, guides, inserts, wide-band work rolls, forged steel rolls, arbor rods and drums, and mill rolls. We mainly serve with the fields of steel manufacturing, wire rod manufacturing, pipe manufacturing, cold rolling and hot rolling technology, mill manufacturing, etc.

Cemented Carbide Tools for Hot Rolling

Cemented Carbide Tools for Hot Rolling - SPP CARBIDE Manufacturer

The company has 30 years of experience in the manufacture of hot and cold rolling replacement parts, supplying tungsten carbide, carbide, technical ceramics, hardened steel replacement parts and tooling to renowned Chinese and European steel, wire rod and tube manufacturers.

Typical Products:

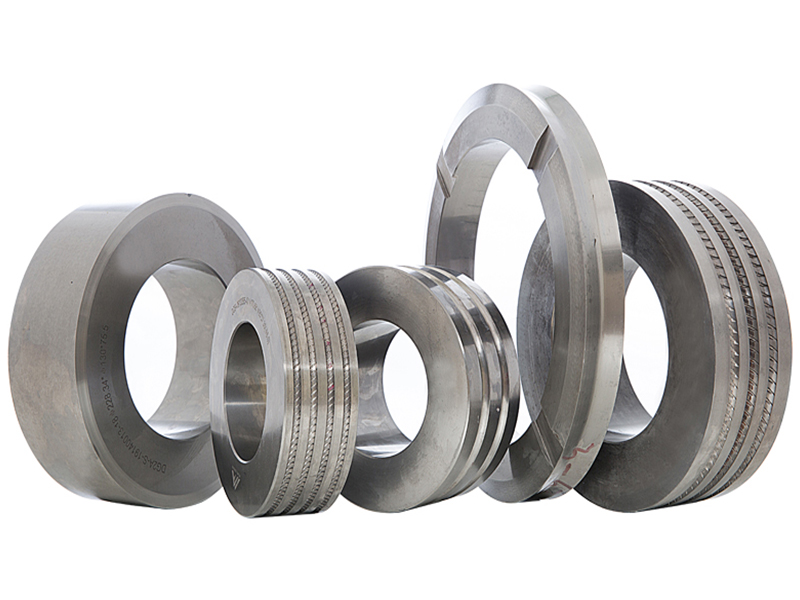

Rod and Coil Rolling Mill Rolls Rings

Tungsten Carbide Rolls

Wire Guide Wheels

Torsion Rolls

Tilt Rollers

Cooling Nozzles

Inlet and outlet wire guides

Cemented Carbide Compoite Roll

Three Carbide Rings

HSS Rolls, etc.Tungsten Carbide Rolls for Hot & Cold Rolling

Tungsten Carbide Rolls

Tungsten carbide tooling and components such as tungsten carbide rolls, nozzles, inlet and outlet wire guides, clamping systems, and rollers for hot and cold rolling of long steel products such as wire rod, bars, and tubes.

SPP CARBIDE LLC's 30+ years of experience in mill applications, coupled with our wide range of tungsten carbide rolls, tungsten carbide nozzles, inlet and outlet wire guides, and torsion roll rings customised to meet the needs of the marketplace, gives us the unique ability to work with you to develop an effective solution specifically tailored to your mill needs. Our custom solutions include tungsten carbide block rolls, combination rolls and carbide casting solutions as well as various clamping solution alternatives.

Product Group:

Cast Carbide Rolls

Composite Rolls

Tungsten Carbide Rings

Tungsten Carbide Rolls

Wire Guide Rolls

Torsion rollers

Tilt Roller

Carbide cooling nozzles

Inlet and outlet wire guides

Ring rolls

Rodillos arrastradores

Feeding rolls

Nozzles

Guiahilos

Wire guides

SPP Industry Ltd.

In the 1990s, SPP Industry Ltd was one of the first manufacturers to establish CNC machining in China. The company has now established five major machine parks in China, with significant achievements in the areas of 5-axis machining, precision grinding & honing, gear machining, large parts machining, custom tungsten carbide and new material development respectively.