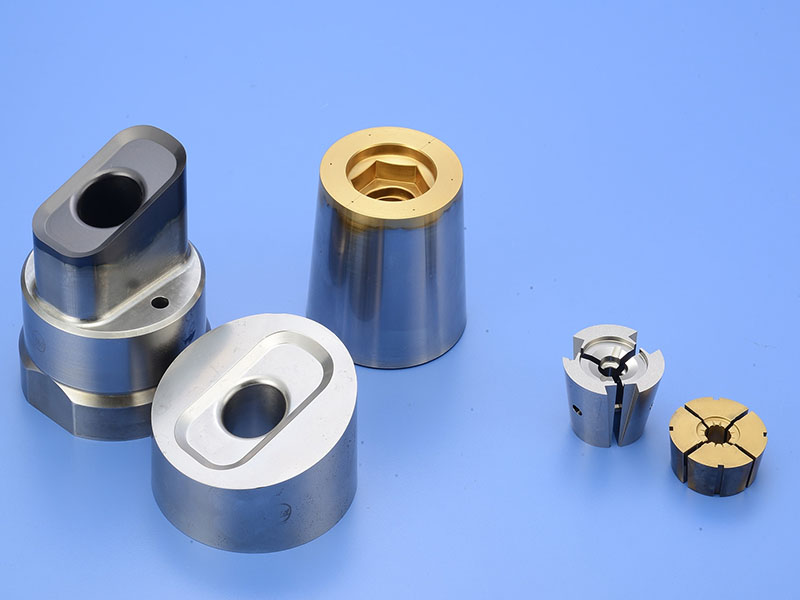

Hot & Cold Forming Trimming Dies & Inserts

We offer precision tooling making for the cold & hot forging sector, they are generally made of carbide, M42, M2, HSS, 1.3343, ASP60 and others.

Hot & Cold Forming Dies & Inserts

Die Assembly

Steel Inserts

Carbide Inserts

Segmented Carbide Inserts

Replaceable Carbide Inserts

Trimming Dies

Open Dies

Die Screws

Die Fillers

Serration Heading Dies

Die Sleeves

Pointing Dies

Die Fillers

and more.

At SPP CARBIDE, our primary goal is to produce tools that last as long as possible.

Since 1994, we've been helping our customers double or even triple the life of their tools, keep their machines running, produce more parts without having to replace inserts or mold components, and increase overall productivity and profitability. In addition, more reliable tooling reduces the need to purchase parts. Several case studies document how the SPP CARBIDE team has worked with customers to keep our tools running for an entire run, whereas in the past runs required three sets of tools to achieve the same number of parts.

Specialist capabilities

SPP CARBIDE has specialized capabilities in the production of carbide and steel blades. Many shops deal with only one aspect of the tooling, whether it be pins, housings, inserts, special blades, punches, cold heading dies, shaping dies, etc. At SPP CARBIDE, we can easily manufacture an entire tool kit that includes all the tools needed to produce the finished product. This includes feed wheels, sleeves, cutters, knives, transfer fingers, die assemblies, punches, strippers, and other items as needed.

Our Customer Base

SPP CARBIDE's customer base produces parts such as male fasteners, ammunition, rivets, bearings, medical devices, medical tablets, battery terminals, electrical connectors and more.

SPP CARBIDE has experts who work with our customers to help them select the right materials to maximize mold life. We work closely with outside engineers and other industry experts to ensure that the highest quality molds are produced, resulting in the best possible parts according to individual industry standards.

Related products

Automotive Tungsten Carbide Custom Tooling Macining

Automotive Technology

We help keep the automotive industry alive.

New innovations, changing products and customer demands have made flexibility and adaptability part of manufacturing in the automotive industry, as has the production of tools and dies used in the automotive market. The tools and mold solutions produced need to be flexible, precise and durable to withstand the rigors of automotive manufacturing and create a significant return on investment to help you stay competitive.

SPP CARBIDE offers tool manufacturing services in a wide range of materials such as tungsten carbide, technical ceramics, steel, aluminum alloys, etc., which are perfectly suited to meet the custom tooling machining requirements of the automotive and new energy vehicle sectors.Cold Forming Tooling and Cold Forging Die

Cold Heading Tooling includes:

Carbide and Steel Inserts

Extruding Dies

Taptite ® Inserts

Torx ® and Torx Plus ® inserts

Strux ® Tooling

Magform ® Tooling

Die Cases and Punch Cases

Sleeves

Trim Dies

Cut Off Knives

Quills

Nut Forming Tooling

Knock out pins

Punches

Steel and Carbide Extrusion Pins

Feed Rolls

Prototypes

Machine Parts

Wear Coatings

Carbide DIES

Carbide PVD coated punches

Shaping Dies

Tungsten Carbide Inserts

Taptite

Taptite 2000

T Tap

Torx

Torx Plus

RemincScrews Header Punches (Second Punch)

Screw Head Punches (Screw Second Punches), Second Head Punches manufacturers and suppliers.

Phillips punches, screw punches, slotted punches,Recess Punch, Header Punch,second punches, Header punch dies

The header punches are for various screw drives recess like phillips, slotted, phillips slotted, 6 lobe, 6 lobe tamper, 6 lobe slotted, pozi, pozi-slotted, hexagon, spanner, phillips-slot.ind, slot.ind or customized design.Head punches are available for ANSI, JIS, DIN or ISO standards for flat, oval, bundled, pan(JIS), pan(ANSI), round, truss, button, disc washers, cheese, tin TiALN screw head punches thread rolling dies, upsetting dies and fillers. It is also available in custom designs. Please provide us with your detailed specifications or screw drawings for our reference when you enquire or order.

Materials: M2, M42,HSS,Carbide,ASP23,1.3343 etc.

Finishes: plain, TiN, TiALN coated. Fastener forming tool manufacturer.Hot & Cold Forming Punches & Pins

Forming tools

We manufacture customer designed punches, dies and auxiliary tools using a wide range of carbides and steels to provide the ultimate solution for maintaining high performance.

Our advantages: 1: Reduced production costs, by maintaining efficiency and reducing downtime. 2: Improved product performance, through heat treatment and various PVD coatings to extend tool life. 3: High precision, state-of-the-art CNC machining to form complex shapes for multi-stage upsets.

SPP Industry Ltd.

In the 1990s, SPP Industry Ltd was one of the first manufacturers to establish CNC machining in China. The company has now established five major machine parks in China, with significant achievements in the areas of 5-axis machining, precision grinding & honing, gear machining, large parts machining, custom tungsten carbide and new material development respectively.