Mould Components for Optical Components Manufacturers

The company is very well positioned in the field of moulding tool manufacture for optical components and has become a well-known Chinese manufacturer of optical components and a gold supplier in the field of research.

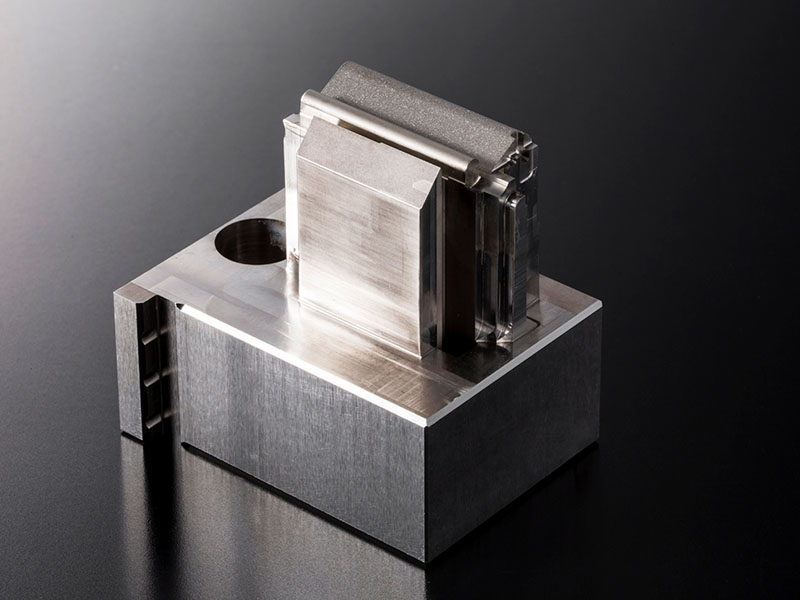

We supply mould components for the forming of optical components including, cores and inserts, slides and die kernels, cavities and cavities, templates and overlay components, punches and matrices.

Optical moulds are cavity shaped jigs for injection moulding optical products.

Optical moulds are defined by the use of specialised optical materials with a nano-hardening and wear-resistant treatment. It can be used 350,000 times. Optical precision Rt<0.5um, roughness Ra<0.01um and finish of class 3. In addition, the rigidity and impact resistance of the material must be taken into account when designing the performance of different products. Also need to know the characteristics of the optical injection molding material: such as: PMMA-1000 refractive index 1.43217 shrinkage 1.0026. so that the mold can be made to meet the ideal design requirements.

Manufacture of optical mould components from drawings

Application areas for optical mould elements:

-Car lights

-Automotive optical components

-Lens and lens manufacturing

-Microscopes, monitors, rear view mirrors, etc.

-Biological and medical

-Aerospace

-Precision machinery, etc.

Related products

Automotive Lens & Mirror Forming Die Tooling and Parts

The company has 16 years of experience in the manufacture of moulded components for automotive lenses and lens moulding. We manufacture moulded components and tools for optical components, which consist of tungsten carbide or hardened tool steel with a rigorous mirror finish.

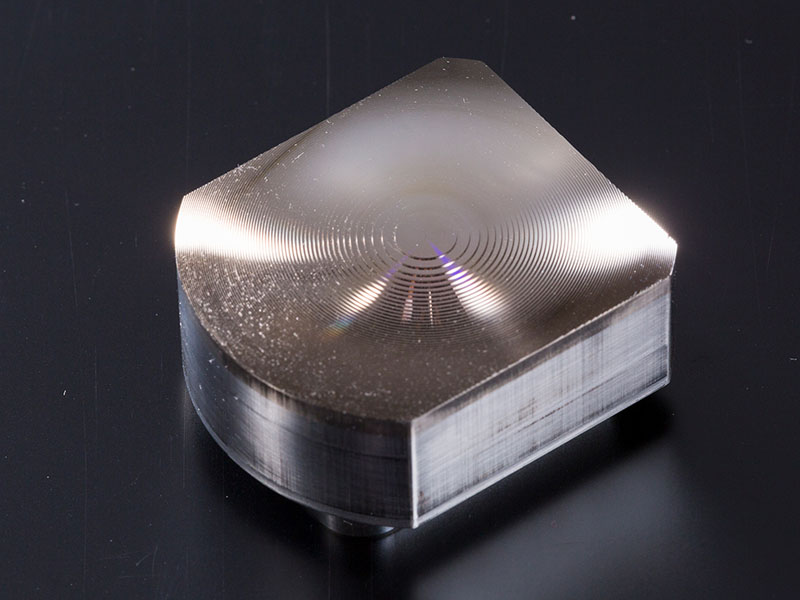

Fresnel Lenses Machining for Optical Tooling Components

Advantages of Precision Machined and Custom Fresnel Lenses and Fresnel Lenses.

Physically, the Fresnel lens has a narrow profile that focuses light similar to a conventional optical lens, but has several advantages over its thicker counterparts:

Light weight: a very interesting option in situations where weight is important (automotive, aerospace, etc.);

Large format: Fresnel lenses are very useful for standard and wide-angle applications;

Various substrate materials: substrate materials vary from acrylic to polycarbonate and glass.

Performance: excellent light gathering capability.High Speed 5-axis Milling of Die-Cast Mould Components

SPP INDUSTRY specialises in five-axis CNC machining services, including five-axis high-speed milling, five-axis machining centres, five-axis gantry milling, five-axis cube milling, large five-axis machining centres and more.

Supported materials:

-Hardened steel

-Copper and beryllium copper

-Nitrided steel

-Martensitic stainless steel

-Carbide

-Technical ceramics

-Titanium and high temperature alloys etc.Injection Moulding for Sophisticated Plastic Optical Components

We supply mould components for the optical sector, including injection moulding tools and moulds, microfluidic components, silicone optical injection mould components, mould components for optical components for automotive headlamps, sensor optical mould cores and inserts, cavities and core pins for micro-optical moulds for camera systems, mould punches and bushings for LED lighting systems, etc.

Material: 1.2343/1.2344/HSS/SKD11/SHH51/M42/M2/ASP23/Tungsten Carbide/Technical Ceramics/Beryllium Copper etc.

SPP Industry Ltd.

In the 1990s, SPP Industry Ltd was one of the first manufacturers to establish CNC machining in China. The company has now established five major machine parks in China, with significant achievements in the areas of 5-axis machining, precision grinding & honing, gear machining, large parts machining, custom tungsten carbide and new material development respectively.