Powdered Metal Compaction Tooling & Sintering Tooling

Powdered Metal Compaction Prees Tooling & Sintering Tooling & Carbide Dies

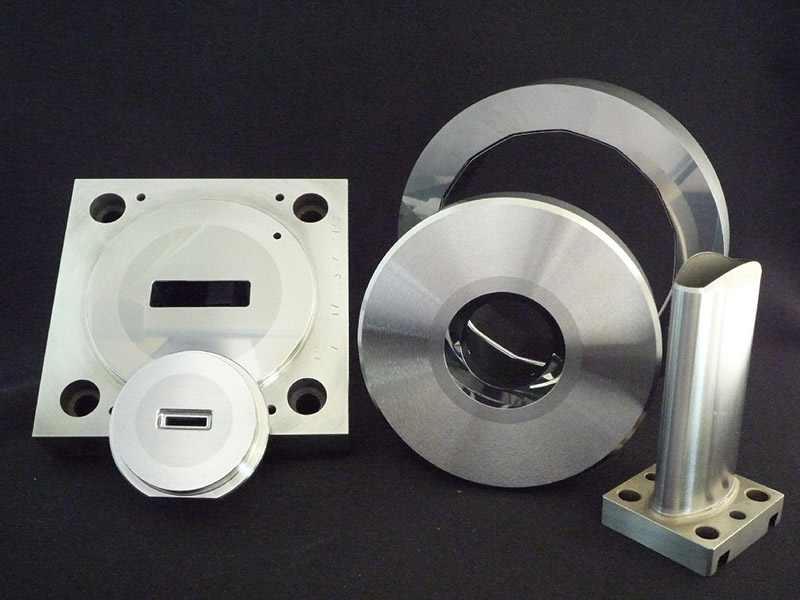

SINTERING TOOLING

The construction of dies and punches for the sintering of metal powders requires equipment of high accuracy, repeatability and autonomy. SPP CARBIDE DIE is not only equipped with these mentioned methods, but also adapted them automated and robotic.

This makes it one of the best companies in the world for the production of tools for pressing, sintering and shaping of metal powders.SPP CARBIDE DIE has modern high speed machining centers and Swiss wire spark machines and Swiss EMDs for machining complex frontal contours of upper and lower punches with hardnesses ranging from 60-64 HRc after heat treatment.SPP CARBIDE DIE has also developed different grades of Carbide DIE has also developed different grades of carbide punches.

SPP CARBIDE's Specialties

From simple single-layer parts to the most complex multi-layer structures, our engineering and production capabilities allow us to offer a complete line of production tooling that is manufactured to customer-approved designs that meet the required stamping specifications and part tolerances. We specialize in high-value, high-complexity tooling components with tight tolerances and surface finishes for new and replacement tooling, retrofits, fixtures, prototypes and general precision machined parts.

Our specialized services include

- Powder metallurgy compaction tooling & dies design and manufacturing

- Ceramic compaction tooling & dies design and manufacturing

- Carbide tooling and machining

- Precision carbide machining

- Gears (spur, helical, bevel, Grotto, modified)

- Extrusion molds and components

- Gauges

- Small lot precision production

- General machining

- Hot forging molds for PM parts

- Dry pressing of polycarbonate powders

- Refurbishment and repair of existing tools

Our Precision Metalworking Capabilities

- CNC turning and milling

- Precision hard machining

- CNC Countersinking (Tie Rod) EDM

- Wire Cut Electrical Discharge Machining

- Small Hole EDM

- CNC Jig Grinding

- Internal & External Cylindrical Grinding

- Surface grinding

- Vertical Grinding and Honing

- Uncircular and eccentric grinding

- Gear and sprocket grinding

- Laser etching and engraving

- Micro laser welding

TYPES OF POWDERED METAL TOOLING

Compacting Dies and Punches

Carbide Punches and Dies

Powdered Metal Compacting Dies

Compacting Core Rods

Ammunition Compacting Dies

Other Powdered Metal Tooling

Related products

Pot & Plunge for Semiconductor Packaging Tooling

We supply mould components for semiconductor packaging, integrated circuits, they are completed with carbide, technical ceramics, hardened tool steel.

Typical products:

Strip Cavity

Pot & Plunger

Ejector Pins

Cavity QFP

Cavity - T2R

Cavity - SFLAT

Cavity - QFN

Cavity - ESOP

Tungsten Carbide Speciality Inserts

Mould Inserts

Punch & Matrix

Guidance elements, etc.Ammunition Tooling & Custom Carbide Dies

We can provide tooling and services for ammunition producers in a variety of applications, including:

Steel casings

Sleeves

Fillers

Backing nuts

Carbide inserts

Steel inserts

Pins

Knock outs

Punch casings

Transfer fingers

Feed wheels

Impact dies

Quills

Cut off knives

Die block holders

Crimping dies

Lujan dies etc.Precision Tungsten Carbide Drawing Dies Manufacturer

SPP INDUSTRY develops and manufactures all types of wire drawing dies: round, oval, square, hexagonal, quadrilateral and other special shapes. The company can produce any drawing requirement you need. Based on our 23 years of experience in the manufacture of tungsten carbide tools, we will also be able to help you design your drawing dies and select the most suitable grade of carbide for your production.

OEM/ODM Custom Machining Carbide Punches and Buttons

Tungsten carbide punches and matrices with high hardness and wear resistance are more suitable for stronger working conditions than tool steel (1.2379) or HSS.-Pressing punches and dies

-Bullet making punches and Buttons

-Carbide drawing dies

-Carbide Cold Heading Punches and Buttons

-Hot forged carbide punches and tools

-Punch and Buttons for stamping dies

-Punch for automotive wheel manufacturing dies

-Cutting punches for wire forming

-PVD coated punches and Buttons

-Punch manufacturing according to DIN 9861 and ISO 8020, etc.

SPP Industry Ltd.

In the 1990s, SPP Industry Ltd was one of the first manufacturers to establish CNC machining in China. The company has now established five major machine parks in China, with significant achievements in the areas of 5-axis machining, precision grinding & honing, gear machining, large parts machining, custom tungsten carbide and new material development respectively.