Precision Cam Manufacturing Cam Grinding Service

The cam manufacturing service uses specialised equipment, such as machining and turning centres under CNC computer control, to produce cams to customer specifications. The manufacturing process is capable of producing a wide range of pieces, from small detailed parts to large castings. Cams can be made from a variety of materials including high temperature alloys such as nickel and titanium alloys. The cam manufacturing service can update old cam data and provide cam designs (manufacturing output files and/or master cams) as required.

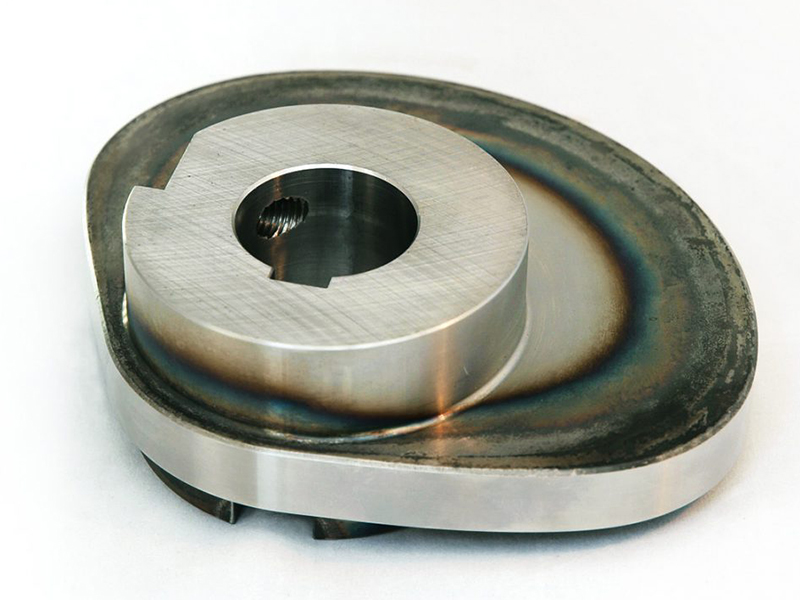

We offer a wide range of cam manufacturing services, some cam examples:

-Disc type cams

-Barrel cams

-Conjugate cams

-Cams and camshafts

-Grooved cams

-Cylindrical cams

-Grooved wheels

-Cam indexing mechanism

-Cam assemblies etc.

Manufacturer of cams and camshafts from drawings

A cam is a member with a curved profile or groove, generally the active part, which moves in a constant rotary or reciprocating linear motion. Cam mechanisms are reliable and are therefore widely used in automatic machine tools, internal combustion engines, printing presses and textile machines.

Related products

High Precision Centreless Grinding Services Manufacturer

We offer a high precision centreless grinding service with an accuracy of up to 0.001. Centreless grinding guarantees the true roundness and concentricity of the components and is therefore very suitable for the manufacture of ancillary components.

For example:

-Hydraulic components

-Hydraulic spools and sleeves

-Valve stems

-Tungsten carbide fluid components

-Technical ceramic pin gauges

-Gauges and gauges

-Technical ceramic rods etc.Ceramic & Tungsten Carbide Coated Components Machning

Service for ceramic coated parts and tungsten carbide coated parts

-Ceramic coated shafts

-Tungsten carbide coated shafts

-Ceramic coated parts

-Tungsten carbide coated parts

-Ceramic coated bushings

-Tungsten carbide coated wear partsThread & Tooth & Gear Grinding Manufacturer

We offer thread grinding, gear grinding and tooth grinding services.

-Gear shafts

-Worm shafts and worm wheels

-Gear grinding

-Threaded shafts

-Threaded cores

-Micro pinsCustom Manufacturer of Special Collets & Guides

We manufacture special collets and guides, including ER collets.

Manufactured from spring steel, if you have other material options please send us a drawing for evaluation.

SPP Industry Ltd.

In the 1990s, SPP Industry Ltd was one of the first manufacturers to establish CNC machining in China. The company has now established five major machine parks in China, with significant achievements in the areas of 5-axis machining, precision grinding & honing, gear machining, large parts machining, custom tungsten carbide and new material development respectively.