Rolling Mill Rolls

Mill Rolls

SPP CNC MACHINING customised specialists for the best solution for you!

SPP CNC MACHINING is a company specialising in the customisation of precision components. With years of experience and advanced production equipment, we can provide you with high quality and reliable roll products.

Our mill rolls are suitable for all kinds of metallurgical industries, including the production of bars, wires, profiles, strips, tubes and so on. We can customise the rolls according to the specific requirements and application scenarios of our customers to ensure their performance and longevity in various environments.

Material options: tungsten carbide, high speed steel, cast steel, ductile iron, tungsten carbide coating, etc.

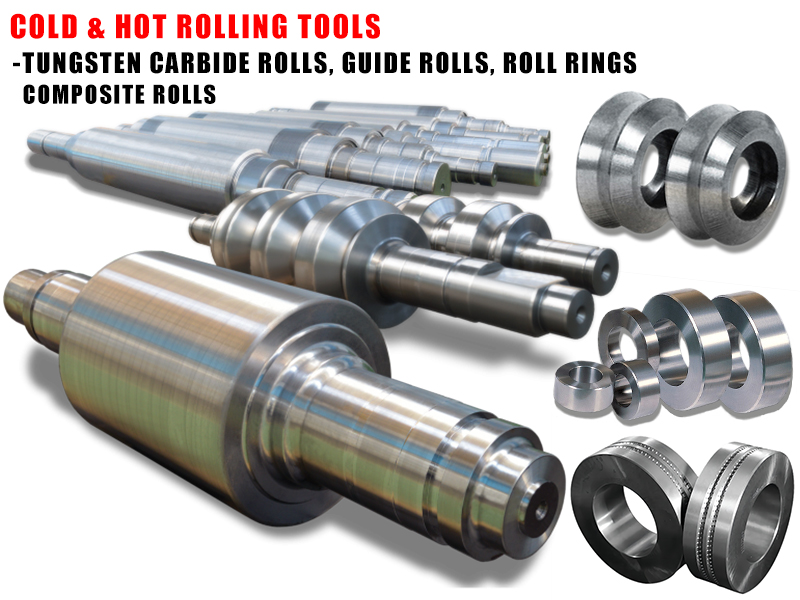

Typical product examples of mill rolls:

Tungsten carbide rolls

High speed steel rolls

High chrome steel rolls

Graphite steel rolls

Mill Roll Manufacturing Plant

Semi-steel rolls

Steel rolls for mill rolls

Alloy cast steel rolls

Centrifugal cast iron rolls

Bainitic ductile iron rolls

Alloy rolls, tungsten carbide rolls

Rolls for rolling mills

Alloy cold hard cast iron rolls

Alloy infinite cold hard cast iron rolls

Rolls for rolling mills for medium plate mills

Strip mill rolls

Mill rolls for hot strip mills

Rolls for cold strip mill

Manufacture of rolls according to drawings

Roll applications:

Pipe manufacturing, tube manufacturing, wire rod manufacturing, steel manufacturing, metal metallurgy, cold and hot rolling technology, etc.

Related products

Carbide Cooling Nozzles for Cold and Hot Rolling

Nozzles for roll cooling

Optimum roll cooling in hot and cold rolling mills

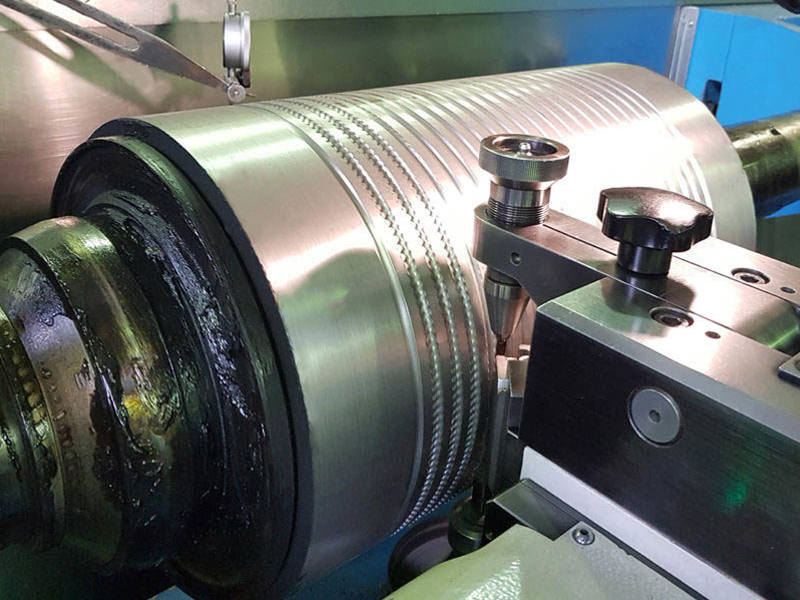

During the rolling process in hot and cold mills, heat is generated by mechanical deformation of the rolled parts due to frictional deformation. Effective cooling of the work rolls and support rolls (if necessary) is therefore essential for the forming process to ensure stable roll temperatures as well as efficient heat transfer and heat dissipation. Therefore, the goal is to create uniform, even cooling over the entire roll width with a homogeneous and acceptable heat distribution.

SPP CARBIDE produces cooling nozzles for hot or cold rolling mills. The use of tungsten carbide nozzles with either an integral tungsten carbide or a shell steel core allows for tens of times the failure of normal stainless steel.

Material options: tungsten carbide, high-speed steel, stainless steel, etc.Cold and Hot Rolling Tools-Tungsten Carbide Rolls

SPP CNC MACHINING has been researching, developing and producing tungsten carbide rolls and HSS rolls since 1994. We have patents for a number of products such as tungsten carbide rolls, casting rolls, HSS rolls, roll rings, composite rolls, guides, inserts, wide-band work rolls, forged steel rolls, arbor rods and drums, and mill rolls. We mainly serve with the fields of steel manufacturing, wire rod manufacturing, pipe manufacturing, cold rolling and hot rolling technology, mill manufacturing, etc.

Tungsten Carbide Rolls for Cold and Hot Rolling

We are a supplier of precision rolls for the cold rolling and steel processing industries. The integrity of the rolls affects the productivity and availability of the mill. The rolls are designed for optimum utilisation and are ultrasonically tested. Our customers speak highly of the performance of our range of rolls. Being a renowned name in the industry, we offer superior quality Tungsten Carbide Rolls. Our rolls are exported to various countries of the world. Being a renowned name in the industry, we are committed to provide superior quality Tungsten Carbide Rolls.

Product Features

Material: Integral tungsten carbide, tungsten carbide coating,D3, D2, 52100, HSS, Hot Die.

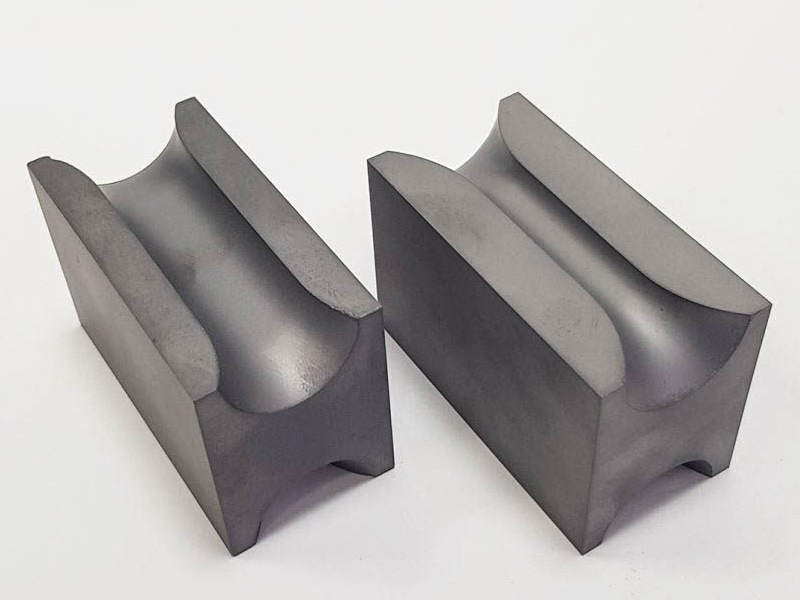

Application/Use: For MillsWire Straightening & Guiding Dies for Steel Forming

SPP CARBIDE Inc. manufactures outstanding wear resistant wire straightening dies for your wire drawing operation. Our global customers come to us not only because of our quality and price, but also because of our short lead times for producing wire straightening dies of any size. Our tungsten carbide moulds provide excellent wear resistance in all sizes for your wire drawing and tube drawing processes. If you are looking for a quote for a mould, please fill out the form below and we will be happy to quote your part!

SPP Industry Ltd.

In the 1990s, SPP Industry Ltd was one of the first manufacturers to establish CNC machining in China. The company has now established five major machine parks in China, with significant achievements in the areas of 5-axis machining, precision grinding & honing, gear machining, large parts machining, custom tungsten carbide and new material development respectively.