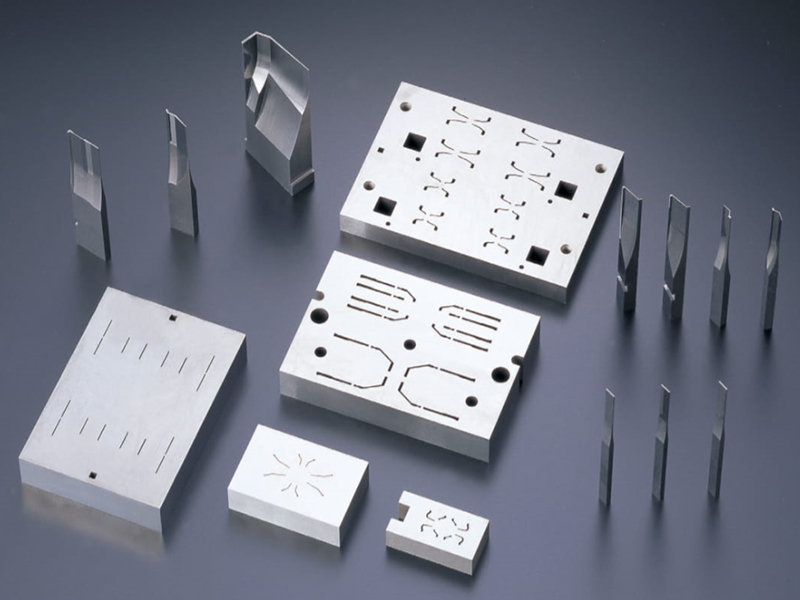

Rotor and Stator Carbide Dies for Motor Tooling

Cemented Carbide for Progressive Dies

Finished carbide products requiring micron-level tolerances, such as punch dies for motor cores and carbide parts for stainless steel, copper, and aluminum. Precision machined by SPP CARBIDE manufacturers and delivered ready for use.Tungsten carbide progressive die tools and components are used in the manufacture of rotor and stator dies in electric motors and are manufactured from tungsten carbide to an accuracy of 0,001.

We can manufacture various grades of silicon steel stacks including fully or semi-machined stators and rotors, bulk fields and armatures as well as interlocking and automatic riveted cores, AC/DC motor stators and rotors, induction motor stators, brushless motor stator and rotor, stepper motor stator and rotor, SR motor stator and rotor, permanent magnet motor stator and rotor, general purpose motor stator and rotor, and more.

We also provide high precision customized tungsten carbide tools for motor rotors and stators, which are made of tungsten carbide for more durability and accuracy assurance.

Manufacture of rotors for electric motors and customized tungsten carbide molds & dies and tooling according to drawings.

For use in motor manufacturing

Related products

Pot & Plunge for Semiconductor Packaging Tooling

We supply mould components for semiconductor packaging, integrated circuits, they are completed with carbide, technical ceramics, hardened tool steel.

Typical products:

Strip Cavity

Pot & Plunger

Ejector Pins

Cavity QFP

Cavity - T2R

Cavity - SFLAT

Cavity - QFN

Cavity - ESOP

Tungsten Carbide Speciality Inserts

Mould Inserts

Punch & Matrix

Guidance elements, etc.Ammunition Tooling & Custom Carbide Dies

We can provide tooling and services for ammunition producers in a variety of applications, including:

Steel casings

Sleeves

Fillers

Backing nuts

Carbide inserts

Steel inserts

Pins

Knock outs

Punch casings

Transfer fingers

Feed wheels

Impact dies

Quills

Cut off knives

Die block holders

Crimping dies

Lujan dies etc.Precision Tungsten Carbide Drawing Dies Manufacturer

SPP INDUSTRY develops and manufactures all types of wire drawing dies: round, oval, square, hexagonal, quadrilateral and other special shapes. The company can produce any drawing requirement you need. Based on our 23 years of experience in the manufacture of tungsten carbide tools, we will also be able to help you design your drawing dies and select the most suitable grade of carbide for your production.

OEM/ODM Custom Machining High Quality Carbide Dies

Carbide tooling generally consists of hardened tool steel casings and carbide, and is generally used in forming, bullet manufacturing, daily packaging, cold heading and forging, metal stamping, fasteners, tool making and other fields.

-Drawing Dies

-Cutting, Trimming Dies

-Punches

-Trilobular, Hexalobular Dies

-Extrusion Dies

-Reduction Dies

-Header Dies

-Non-rotating Systems, Locking Bolts

-Ammunition Tooling

-Metal Packaging Tooling

-Sintering Tooling

-Dies With Special Profiles

SPP Industry Ltd.

In the 1990s, SPP Industry Ltd was one of the first manufacturers to establish CNC machining in China. The company has now established five major machine parks in China, with significant achievements in the areas of 5-axis machining, precision grinding & honing, gear machining, large parts machining, custom tungsten carbide and new material development respectively.