Sinker EDM & Wire EDM Service Manufacturers

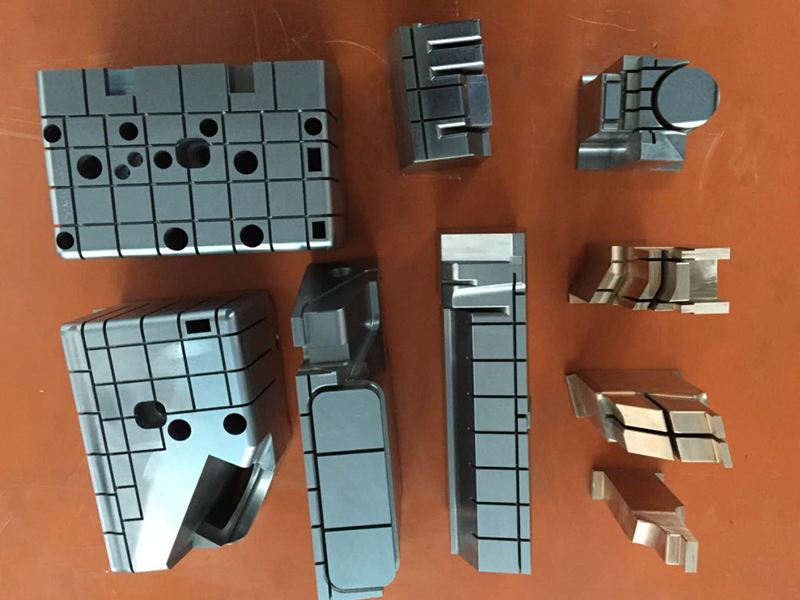

We offer Sinker EDM & Wire EDM services, manufacturing:

-Precision terminal connector mould components-

-Semiconductor mould components

-Injection mould components

-Internal spline components

-Automotive engine cylinders

-Motor core mould components

-Gear and gearbox components

-Electronic components (sensors, microchips)

-Turbine blades, landing gear components and wheel blades

-Medical implants etc.

Electrical discharge machining (EDM machining) is a controlled metal removal process for removing metal by means of electric discharge machining. In this EDM process, electric discharge (erosion) is used as a cutting tool to cut the workpiece to produce a finished part of the desired shape

Component customisation service from drawings

Applications of EDM and WEDM:

Automotive sector: Cars and other automobiles have several complex parts that require high precision machining. EDM wire cutting is suitable for the manufacture of engine cylinders, gears and gearboxes, fuel injectors and other components.

Electronic components: Micro components used in electronic products can be produced by wire EDM machining. These components include sensors, microchips, connector mould assemblies, etc.

Aerospace: The aerospace industry uses EDM wire cutting to manufacture parts that require high precision and dimensional accuracy. The process can produce turbine blades, landing gear components, nozzles and wheel blades.

Medical products: EDM wire-cutting is suitable for the manufacture of surgical implants, prostheses and other medical devices.

Mould, tool and die making: EDM wire cutting can make moulds and dies for a variety of manufacturing processes, including injection moulding cavities and die kernels, blow moulding cores and inserts, die casting, stamping technology punches and bushings, etc.

Defence sector: bullet manufacture requires high precision EDM machining of the inner cavity, typically made from tungsten carbide material with hardened steel for the outer casing, we supply precision tungsten carbide moulds for bullet manufacture.

Automation field: Automatic dispensing systems generally require tungsten carbide nozzles and firing pins, nozzles are generally manufactured from small bore EDM, we can finish micro bore parts to 0.005.

Precision machinery: some internal splines are generally completed by precision WEDM in order to ensure a good fit with the spline shaft.

Related products

IC Package Mold Parts Cavities and Inserts

We offer fabrication and customization services for semiconductor die components, including:

-IC encapsulation die cavities and inserts

-IC leadframe stamping die punches and bushings

-Semiconductor packaging die plungers and pots, -Semiconductor packaging die plungers and pots

-Encapsulation die cores and core pinsMaterials: tungsten carbide, technical ceramics, tool steel, HSS, ASP23, etc.

EMD Machining Mold Parts for Headphone Manufacturing

We supply precision components according to drawings for the field of acoustic system tooling and tool manufacture, they are machined by EDM and WEDM.

Injection Moulding for Sophisticated Plastic Optical Components

We supply mould components for the optical sector, including injection moulding tools and moulds, microfluidic components, silicone optical injection mould components, mould components for optical components for automotive headlamps, sensor optical mould cores and inserts, cavities and core pins for micro-optical moulds for camera systems, mould punches and bushings for LED lighting systems, etc.

Material: 1.2343/1.2344/HSS/SKD11/SHH51/M42/M2/ASP23/Tungsten Carbide/Technical Ceramics/Beryllium Copper etc.

Motor Die Parts For The Manufacture of Rotor and Stator Stacks

Dongguan spp industry Co.,Limited has the most professional OEM / ODM project management team with many years of experience in mould component manufacturing. We pay special attention to the professional training of our staff, and constantly upgrade and improve our processing technology. SPP INDUSTRY will be your most professional and reliable choice for outsourced parts processing.

Customised parts, European and Japanese brand machines, precision manufacturing

(Grinding 0.002mm / Wire EDM 0.002mm / Discharge EDM 0.005mm / CNC machining 0.005mm)

SPP Industry Ltd.

In the 1990s, SPP Industry Ltd was one of the first manufacturers to establish CNC machining in China. The company has now established five major machine parks in China, with significant achievements in the areas of 5-axis machining, precision grinding & honing, gear machining, large parts machining, custom tungsten carbide and new material development respectively.