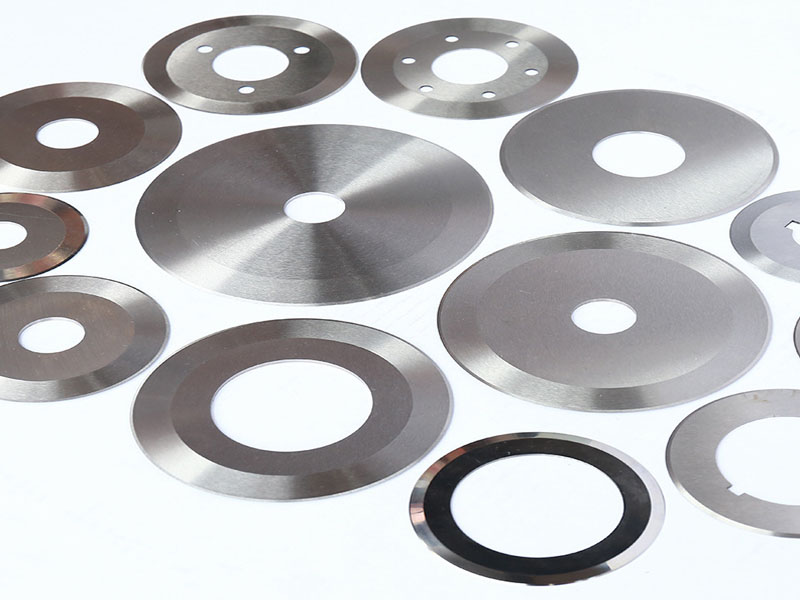

Tungsten Carbide Circular Knives

Manufacturer of Circular Knives

We produce a wide range of knives for a variety of applications from a minimum diameter of 2mm to a maximum of 950mm and offer specific solutions for cutting any job.

We have specialised in manufacturing knives for over thirty years to cut a wide variety of materials such as cardboard boxes, plastics, rubber, cork, deep frozen goods, rubber tubes with or without metal weft yarns, paper tubes and foam. The tool material depends on the material to be cut and the productivity needs of the customer. dongguan spp industry Co.,Limited uses different steels (carbide, diamond, sapphire, ruby, HSS, hardened tool steel, martensitic stainless steel SUS630, etc.) and offers a wide range of solutions for all applications.

The tool shape is very important; the standard shape for common applications is defined by a sharpening type that can be single or double bevelled. Round knives are usually as sharp as straight knives and can have or not have teeth depending on the material being cut. Technological advances in blade geometry and the experience we have gained in several applications have shown that for certain materials a specific tooth shape or a specific kerf significantly improves cutting performance. We usually design and produce tools for specific customers.

For over thirty years we have been manufacturing knives for applications cutting a wide variety of materials. Such as all production of cardboard for corrugated packaging, paper tubes, paper, deep frozen goods, cork, hoses, meat cutting in food processing, woodworking in garden art, forestry cutting, or hoses without metal braid, plastic rubber, foam, etc. We also manufacture and OEM round knives or tungsten carbide blades for manufacturers of slitters, pelletizers and other machinery.

Our technical room designs special cutting tools every day for all the applications our customers need.

We work with the main machine manufacturers and very often we carry out cutting tests during the installation of the machines.

We invite you to contact us to solve every cutting problem.

TC Carbide and Technical Ceramics Circular Knives

SPP INDUSTRY produces Circular Knives and saw blades in carbide and technical ceramics to cope with all customers' sawing applications. Cemented Carbide (HM) is obtained by synthesising tungsten carbide dust, titanium and tantalum mixed with cobalt powder. The finely mixed material is heated to 1500°C and pressed to obtain very thin molecules to form a single homogeneous solid. The main characteristic of Cemented Carbide is its ability to maintain hardness and wear resistance at the highest operating temperatures even in the most demanding applications.

Technical ceramics are special products obtained by synthesising high temperature resistant ceramic powders, silicon carbide and metal oxides such as chromium, cobalt, nickel, titanium, aluminium and tungsten. Cermet is a material with a hardness between silicon carbide and diamond. It has high resistance to cutting temperatures and can withstand extremely high machining speeds. Cermet produces an excellent surface finish on the material being cut and provides the tool with an extremely long service life.

"Disposable" circular saw blade with teeth in ceramic alloy, uncoated, for cutting medium to low carbon steel, bars or tubes of high thickness, for use on stationary cutting machines such as Amada, Nishijima, Tsune, Kasto, Everising. Not recommended for cutting stainless steel.

"TA" circular sawblades with tungsten carbide teeth, PVD coated.

For cutting mild or high carbon steel or stainless steel.

Solid materials or thick-walled tubes.

For use on stationary machines such as Amada, Nishijima, Tsune, Kasto, Everising.

For highly demanding applications.

TC carbide P.V.D. coated circular saw blades for cutting tubes of medium to high carbon steel with wall thicknesses greater than 3 mm and for cutting stainless steel on automatic sawing machines at higher speeds than tubes with HSS saw blades. Guaranteed high performance cutting of thin-walled tubes, obtaining perfect surfaces and burr-free tubing.

TC carbide P.V.D. coated circular saw blades for cutting tubes with wall thicknesses greater than 3 mm, flying cutters (single or double). The special geometry reduces vibration during the cutting process and facilitates chip evacuation.

TC carbide P.V.D. coated regrindable circular saw blades for cutting tubes with wall thicknesses greater than 3 mm. This saw blade is designed for orbital flight cut-off applications on tube mills. The main features of this product are resistance to fracture carbide tips and low vibration during cutting. The result is a very long blade life for machines: Kusakabe, Linsinger, Mair, Nakata, Oto Mills, Sms-Meer.

TC Carbide P.V.D. coated circular saw blades. One of the challenges faced by the industry is the removal of welds from inside the weld channel, which can seriously affect cutting and blade life. This problem reduces the life of circular saw blades by damaging the carbide tips, especially on standard TCT saw blades.

Due to their special design and reinforced tooth profile, the teeth have a very specific geometry and can therefore withstand heavy duty cutting cycles.

Related products

Tooling and Dies for CNC Special Insert Manufacturing

SPP CARBIDE offers carbide tooling manufacturing services for CNC cutting inserts and tools. Special CNC cutting inserts and tools are manufactured from carbide powder metallurgy and we offer manufacturing of carbide powder metallurgy tooling with a special tungsten carbide liner and a housing made from tool steel.

Products include:

3R tooling

Finished tooling

CNC insert tooling

Magnetic core material dies

Tungsten Carbide Ring Dies

Tungsten Carbide Bar Mould

Tungsten Carbide Ball Mould

Tungsten Carbide Block Mould

Tungsten Carbide Nozzle Mould

Cemented Carbide Drawing DieSlitting Machine Blade

Custom Industrial Slitter Knives

Slitter knives are designed to slit a variety of materials in a variety of applications. Because of their ability to cut materials such as paper, plastics and textiles, they are used in many industries. At SPP CARBIDE, we sell both straight and rotary blades. We can design blades for a variety of machine models and customize each result for our customers. If you need a knife for slitting applications, the SPP CARBIDE team will work with you to find a slitting knife solution that meets your needs.Most slitting blades feature a beveled edge for optimal cutting power. The beveled edge allows the blade to cut through the material rather than making a standard cut. When the primary purpose of a slitter knife is to make a puncture, it has teeth. These teeth gradually create smaller slits, such as those found on tear-off paper products. Our sales engineers can help you determine which blade solution is best for your application.

At SPP CARBIDE, all of our slitting blades are manufactured in-house. As an original equipment manufacturer, you'll appreciate our competitive pricing and fast turnaround times that maximize your profits. If you get our blades as an end user, we will listen to your needs to design a customized solution. We view your business goals as our business goals.

Carbide Cutting Tools

Carbide Cutting Tools

We are specialized in designing and manufacturing high-efficiency tungsten cutting tools. We have advanced machines from brand:ROLLOMATIC,WALTER,MAKINO SEIKI AND VOLLMER. The raw material are from Taiwan CB carbide,SUMITOMO from Japan or Guhring from Germany,and available for Bakzers、PVD coating. The unique design and strict quality management have provides strong guarantee for high-quality, high-efficient and more stable new products.Carbide Components for the Automotive & Medical Tooling

SPP Industries produces semi-finished and finished tools or parts for Tier 1 and Tier 2 suppliers, which include

-Assemblies

-Extrusion inserts (carbide and steel)

-Extrusion punches

-Forming punches

-General metal forming

-Hammer Blades

-Punching pins

-Perforating pins

-Drill inserts

-Specialised fastener tools

-Stamping / laminating tools

-Trimming tooling components-Special collets

-Jigs and fixtures

-Carbide medical core pins

SPP Industry Ltd.

In the 1990s, SPP Industry Ltd was one of the first manufacturers to establish CNC machining in China. The company has now established five major machine parks in China, with significant achievements in the areas of 5-axis machining, precision grinding & honing, gear machining, large parts machining, custom tungsten carbide and new material development respectively.