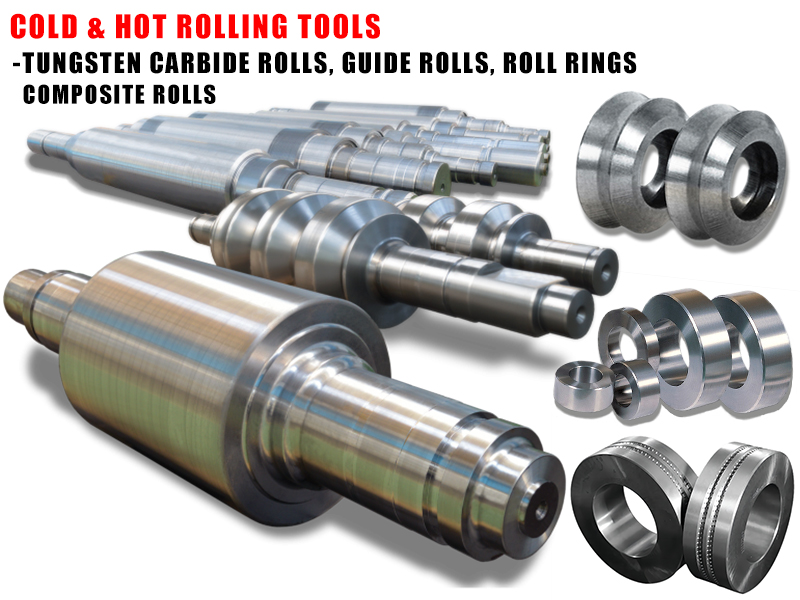

Cold and Hot Rolling Tools-Tungsten Carbide Rolls

SPP CNC MACHINING has been researching, developing and producing tungsten carbide rolls and HSS rolls since 1994. We have patents for a number of products such as tungsten carbide rolls, casting rolls, HSS rolls, roll rings, composite rolls, guides, inserts, wide-band work rolls, forged steel rolls, arbor rods and drums, and mill rolls. We mainly serve with the fields of steel manufacturing, wire rod manufacturing, pipe manufacturing, cold rolling and hot rolling technology, mill manufacturing, etc.

SPP CARBIDE LTD Carbide Rolls define a new standard in carbide rolling applications. As one of the world's largest and most extensive manufacturers of tungsten carbide rolls, SPP CARBIDE has developed a wealth of expertise in developing tungsten carbide solutions to suit your rolling needs.

Economic Advantages

Congui carbide roll rings on hot-rolled seamless steel tube reduction mills last more than 50 times longer than ordinary cast iron roll rings, and the surface quality and dimensional accuracy of the tubes are greatly improved. According to the working conditions (rolling force, speed and pipe diameter) of the seamless steel pipe reduction machine, the use of combined cemented carbide reduction rolls can achieve a high cost performance.

SPP CARBIDE Improved performance

SPP CARBIDE becomes the obvious choice to replace conventional grades SPP CARBIDE is a highly alloyed material designed to improve performance in a wide range of rolling applications The widespread success of SPP CARBIDE rolls is due to the ease of use of the mill and the minimal adjustments required. We also have a choice of materials such as HSS, D2/D3, 1.2379, 1.3343 or tungsten carbide coating.

Manufacture of tungsten carbide rolls, high speed steel rolls, etc. according to drawings.

Roll applications:

-Hot & Cold Rolling Technology

-Mill construction

-Steel manufacturing, etc.

Related products

Tungsten Carbide Rolls for Cold and Hot Rolling

We are a supplier of precision rolls for the cold rolling and steel processing industries. The integrity of the rolls affects the productivity and availability of the mill. The rolls are designed for optimum utilisation and are ultrasonically tested. Our customers speak highly of the performance of our range of rolls. Being a renowned name in the industry, we offer superior quality Tungsten Carbide Rolls. Our rolls are exported to various countries of the world. Being a renowned name in the industry, we are committed to provide superior quality Tungsten Carbide Rolls.

Product Features

Material: Integral tungsten carbide, tungsten carbide coating,D3, D2, 52100, HSS, Hot Die.

Application/Use: For MillsTungsten Carbide Ring Rolls for Cold Rolling

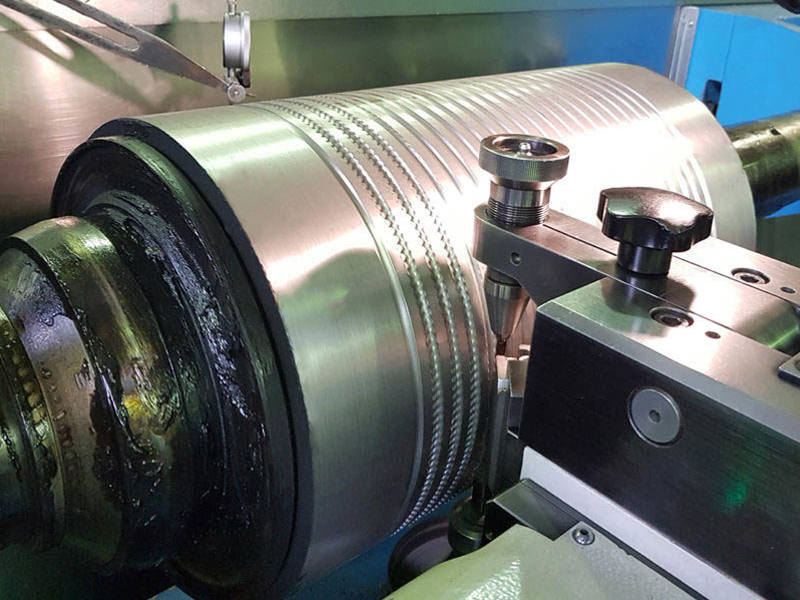

What is cold rolling?

Cold rolling is the use of hot rolled steel coils as raw material, after pickling to remove the oxide skin for cold continuous rolling, the finished product is rolled hard coil, due to continuous cold deformation caused by cold hardening of the rolled hard coil strength, hardness, toughness and plasticity indexes, so the stamping performance will deteriorate, can only be used for simple deformation of the parts. Rolled hard coil can be used as raw materials for hot-dip galvanising plant, because hot-dip galvanising units are set up with annealing line. Rolled hard coil weight is generally 6 ~ 13.5 tonnes, steel coil at room temperature, the hot-rolled pickling coil for continuous rolling.Typical products of carbide tools for cold rolling:

Ring rolls

Rodillos arrastradores

Feeding rolls

Integral straightening dies, or inlaid tungsten carbide straightening and guide pillar dies.

Nozzles

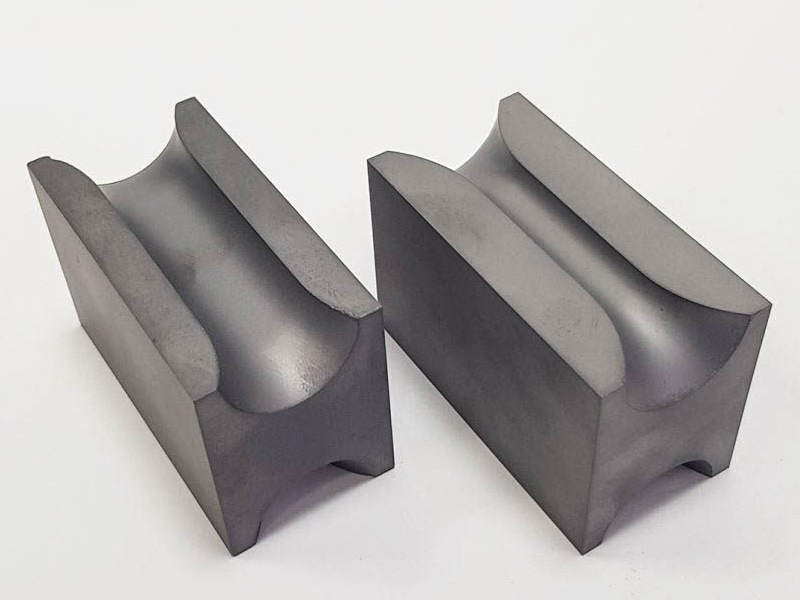

Wire guidesWire Straightening & Guiding Dies for Steel Forming

SPP CARBIDE Inc. manufactures outstanding wear resistant wire straightening dies for your wire drawing operation. Our global customers come to us not only because of our quality and price, but also because of our short lead times for producing wire straightening dies of any size. Our tungsten carbide moulds provide excellent wear resistance in all sizes for your wire drawing and tube drawing processes. If you are looking for a quote for a mould, please fill out the form below and we will be happy to quote your part!

Custom Machining Tungsten Carbide Rolls

SPP CARBIDE produces rolls for cold and hot rolling, where tungsten carbide is the best choice due to the extremely high temperature conditions. We can also manufacture rolls from hardened tool steels such as 1.2379, 1.3343 with tungsten carbide coating on the outside.

Typical products:

-Tungsten carbide rolls

-Tungsten Carbide Rolls

-Crossing rolls

-Shelling rolls

-Pitch Rolls

-Inlet and outlet wire guides

-Torsion rolls

-Wire Guide rolls

-Roll rings

-Rolls Wire Guide rolls

-Titanium wire flattening rolls, rollers

-Plungers for pipe manufacturing

-Guide rails

-Replacement parts, rolls, rollers, etc. for CDA mills.

SPP Industry Ltd.

In the 1990s, SPP Industry Ltd was one of the first manufacturers to establish CNC machining in China. The company has now established five major machine parks in China, with significant achievements in the areas of 5-axis machining, precision grinding & honing, gear machining, large parts machining, custom tungsten carbide and new material development respectively.