Tungsten Carbide Wear Parts for Oil & Natural Gas

Oil and Gas

For over 30 years, SPP CARBIDE has been providing solutions for the oil and gas industry. We offer a wide range of products, from the smallest measuring inserts for drilling to complex and fully finished flow control assemblies manufactured and assembled from a variety of materials. Our fully integrated manufacturing organization allows us to control every step of the process from raw material to finished product. Providing our customers with the best combination of performance, total cost of ownership and availability.

SPP CARBIDE produces tungsten carbide wear parts, hardened steel tooling, and technical ceramic parts for oil and gas applications, mainly in the drilling, production and wireline sectors.

Drilling Products

Equipment used for drilling in the oil and gas industry experience some of the harshest and most demanding conditions in terms of pressure, temperature, and wear. As a consequence, specialized materials such as cemented carbides, diamond, and specialty alloys are necessary to provide the performance and product life that customers require. Hard and SuperHard materials are at the core of SPP CARBIDE’ offerings. Our organization includes a diversified group of companies, including the first manufacturer in China to produce a synthetic diamond. We are a global leader in specialty tungsten and metallic powders with state-of-the-art carbide component manufacturers all of which target specific product segments.

RADIAL BEARINGS

SPP CARBIDE’ radial bearings incorporate hard and superhard materials to minimize the extreme wear conditions experienced in downhole applications. Manufactured to customer dimensional specifications and lined with carbide or TSP on critical wear surfaces, our radial bearings are engineered to increase ROP, allow tighter radius turns, and extend run life.

MWD LWD

Carbide and specialty metal components and assemblies for shielding and wear resistance

MUD NOZZLES

Nozzles and sleeves for drill bits

BUTTONS AND INSERTS

Spherical, conical, ballistic, chisel, and gauging configurations for drilling applications.

PDC SHEAR CUTTERS

Fixed cutter bit inserts utilizing the latest non-planer interface designs for drilling in oil and gas exploration.

DOMED PDC

Domed PDC Inserts for Oil and Gas Drills, Hammer Bits and Gaging

TSP

Inserts for soft formation drilling, gauging, and wear applications

SUBSTRATES

Wide range of carbide grades and surface geometries, engineered for PDC sheer cutters

DIAMOND GRIT

Synthetic diamond grit for oil and gas drills and components

DRILLING STABILIZERS

Downhole drilling stabilizers in multiple configurations including straight, spiral, integral, sleeve, and non-magnetic manufactured to customer specifications.

Production Products

SPP CARBIDE product range for oil and gas production includes artificial lift, flow control, and fluid end components manufactured from hard materials as well as specialty steels designed to improve the performance and extend the life of our customers’ products. From simple, straight walled choke beans to products with complex geometries used in ESP pumps. SPP CARBIDE supplies high-quality materials and components that have made us a leading supplier in this market segment.

PRODUCTS

STAGES FOR ESP

Stage components for electrical submersible pumps.

BALLS AND SEATS

Carbide balls and seats ground to API specifications.

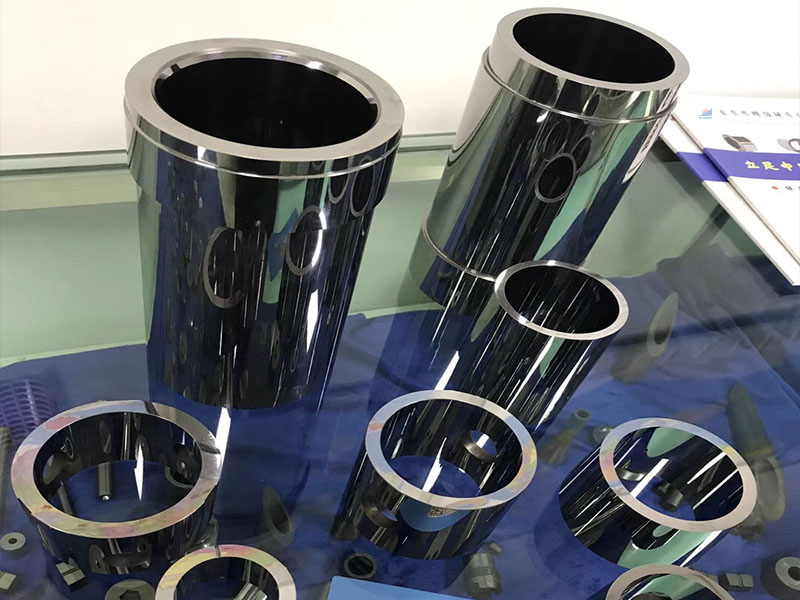

BUSHINGS AND SLEEVES

Standard and specialty carbide grades for ESP pump sleeves.

CHOKE VALVE TRIM

Carbide chokes, seat and points in a wide range of carbide grades.

CAGES

Flow control cages manufactured in standard and alloy-binder grades.

FLUID END

Valves and seats for frac pump fluid ends.

Wireline Products

SPP CARBIDE supports the wireline service business with a full line of products and materials. Products include cables, engineered assemblies, tool strings, runs, fishing and connection tools. We offer a wide range of grades of heavy alloys, stainless steels. tool steel, hard and super hard compositions specifically tailored to meet the individual needs of each application.

Related products

Carbide Valve Seats and Stems

SPP CARBIDE manufactures tungsten carbide wear parts for oil and gas applications.

MWD & LWD COMPONENTS

Mud Deflectors

Valve Seats and Stems

Rotors and Stators

Erosion Sleeves

Flow Restrictor Bearings

Main Pulser Components

Orifices

Solid Carbide or Two- Piece Threaded Nozzles

Seal Rings

Ported Flow Cages

Thrust BearingsCustom Machining MWD, LWD & FE Wear Parts

MWD, LWD & FE Components

We provide gundrilling solutions necessary to support today's, and tomorrow's leading edge Formation Evaluation, Rotary Steerable, Well Completion and reservoir management technologies.M.W.D. COMPONENTS AND L.W.D TOOLING.

Mud Deflectors

Valve Seats and Stems

Rotors and Stators

Erosion Sleeves

Flow Restrictor Bearings

Main Pulser Components

Orifices

Solid Carbide or Two- Piece Threaded Nozzles

Seal Rings

Ported Flow Cages

Thrust BearingsTungsten Carbide Control Valves Spare Parts for Oil and Gas

SPP Carbide manufactures flow control components, Gates and Seats, Bushings, Choke and trim components for oil and gas, where the rigours of extraction and follow-on drilling require extremely wear resistant and hard materials. Cemented carbide and technical ceramics are the first choice and our carbide grades and technical ceramics are perfectly suited to their wear requirements. We also offer a selection of hardened steels and tool steels.

SPP Carbide’s fluid handling and flow control products include:

Homogenizer Components

Spray Nozzles and Swirl Chambers

Centrifugal Pump Components

Choke Valve Components and Cages

Control Valve Components

Gate Valve Components

Mechanical Seal Components

Compressor Components

Centrifuge TilesTungsten Carbide Flow Control Wear Components

Tungsten carbide is an ideal material for demanding wear applications, such as the control of material flow in various pumps.

SPP CARBIDE produces components for use in all conditions and has an exemplary record of quality, speed of delivery and life cycle. Our advanced tungsten carbide grades and ability to provide a 'one stop shop' for all aspects of material production, forming and finishing ensures that each component is manufactured to the highest standards, providing long life and efficient performance.

Our ability to machine components up to 1200mm in diameter and achieve flatness in two light bands makes us the perfect choice for all applications in high pressure pumps, flow pumps, metering pumps and other systems. We can also 'reverse engineer' worn components or those coming to the end of their life cycle to replace existing steel with high performance tungsten carbide.

SPP Industry Ltd.

In the 1990s, SPP Industry Ltd was one of the first manufacturers to establish CNC machining in China. The company has now established five major machine parks in China, with significant achievements in the areas of 5-axis machining, precision grinding & honing, gear machining, large parts machining, custom tungsten carbide and new material development respectively.