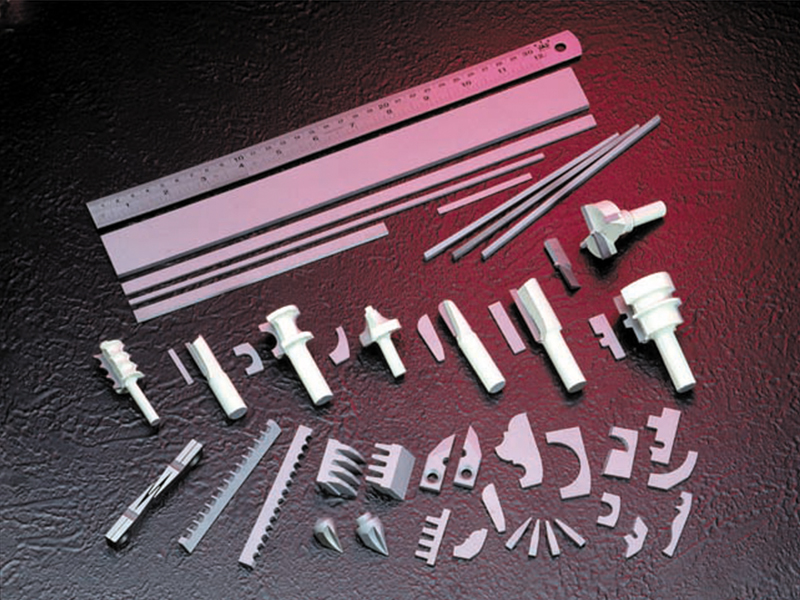

Carbide Battery Tooling & Stamping Die Parts

SPP CARBIDE, LLC provides high precision tungsten carbide tooling, custom carbide component services. The company has been providing precision tooling for battery manufacturing for 10 years, and with the latest developments in the lithium battery field requiring a large number of tungsten carbide tools, SPP CARBIDE is the best choice.

Some examples of tungsten carbide tools for battery manufacturing:

-Lithium battery slitting blade

-Carbide special inserts

-Carbide punches

-Carbide matrix

-Carbide concave moulds

-Tungsten Carbide Dies

-Stamping punches and dies

-Carbide Punches and Dies

-Cut-Edge Rings

-Draw Dies

-Forming Punches

-Trimming Dies

-Stamping Dies

-Core Rods

-Carbide Wire Guides

-Cavities and Cores

-Sliders and Core Pins

OtherCarbide Blades for Woodworking

Bespoke carbide tools and tungsten carbide inserts manufactured entirely to customer drawings for applications in woodworking, forestry, agriculture, etc.

Carbide Components for the Automotive & Medical Tooling

SPP Industries produces semi-finished and finished tools or parts for Tier 1 and Tier 2 suppliers, which include

-Assemblies

-Extrusion inserts (carbide and steel)

-Extrusion punches

-Forming punches

-General metal forming

-Hammer Blades

-Punching pins

-Perforating pins

-Drill inserts

-Specialised fastener tools

-Stamping / laminating tools

-Trimming tooling components-Special collets

-Jigs and fixtures

-Carbide medical core pinsCarbide Cooling Nozzles for Cold and Hot Rolling

Nozzles for roll cooling

Optimum roll cooling in hot and cold rolling mills

During the rolling process in hot and cold mills, heat is generated by mechanical deformation of the rolled parts due to frictional deformation. Effective cooling of the work rolls and support rolls (if necessary) is therefore essential for the forming process to ensure stable roll temperatures as well as efficient heat transfer and heat dissipation. Therefore, the goal is to create uniform, even cooling over the entire roll width with a homogeneous and acceptable heat distribution.

SPP CARBIDE produces cooling nozzles for hot or cold rolling mills. The use of tungsten carbide nozzles with either an integral tungsten carbide or a shell steel core allows for tens of times the failure of normal stainless steel.

Material options: tungsten carbide, high-speed steel, stainless steel, etc.Carbide Cutting Tools

Carbide Cutting Tools

We are specialized in designing and manufacturing high-efficiency tungsten cutting tools. We have advanced machines from brand:ROLLOMATIC,WALTER,MAKINO SEIKI AND VOLLMER. The raw material are from Taiwan CB carbide,SUMITOMO from Japan or Guhring from Germany,and available for Bakzers、PVD coating. The unique design and strict quality management have provides strong guarantee for high-quality, high-efficient and more stable new products.Carbide Cutting Tools for the Paper Industry

Paper converting industry

From paper to cardboard to special cellulose products such as tissue or other items in the hygiene industry, carbide ensures significant results and higher productivity. Compared to tempered tool steels, cemented carbide offers higher pressure and wear resistance. It improves cutting edge stability and thus provides better dimensional accuracy. cutting tools made of SPP carbide achieve excellent cutting results - perfect cutting.

Carbide Special Inserts

SPP CARBIDE specialises in the manufacture of standard carbide inserts and special carbide inserts. All products are manufactured using the latest PVD and CVD coating technology. This wide range of grades allows us to "fine tune" a particular grade to your specific operating needs. We thrive on tight tolerances.

We offer ANSI and ISO standards combined with the industry's tightest tolerance grinding to maximise tool life and reduce cycle times. Add our precision regrinding and/or size reduction programs for the most effective manufacturing cost reduction.

Our carbide insert materials, whether coated or uncoated, are known to perform as well or better than our competitors. We provide not only the manufacture of inserts but also the carbide powder metallurgy tooling for insert manufacture and we are often in competition with other major manufacturers. It is part of our daily routine to cross over directly to our competitors' results and recommend better results.

Carbide Special Tools and Inserts Manufacturer

We are Manufacturer, Supplier, Exporter, Services of Solid Carbide Tools, Counter Bores, Countersinks, Form Cutters, Corner Radious Cutters, Woodruff Cutters, Boring Tools and our setup is situated in Dongguan,Guangdang,China.

We offer manufacturing and OEM services for solid carbide tools and inserts, including:

Counter Bores

Countersinks

Form Cutters

Boring Tools

Woodruff Cutters

Corner Radius CutterCarbide Cutting Tools

Tungsten Carbide Cutting Tools

Brazed carbide and HSS tools etc.Carbide Valve Seats and Stems

SPP CARBIDE manufactures tungsten carbide wear parts for oil and gas applications.

MWD & LWD COMPONENTS

Mud Deflectors

Valve Seats and Stems

Rotors and Stators

Erosion Sleeves

Flow Restrictor Bearings

Main Pulser Components

Orifices

Solid Carbide or Two- Piece Threaded Nozzles

Seal Rings

Ported Flow Cages

Thrust BearingsCemented Carbide blades and Tools for Woodworking

Cemented Carbide Tooling for Woodworking

The right choice for every applicationAre you an expert in woodworking? Cemented carbide is a popular material for processing a wide range of wood and wood construction materials. High cutting speeds and long service life are two convincing arguments for using our carbides.

SPP CARBIDE is your contact person for hard metal products. Our product range offers you solutions for all areas of application.

Cemented Carbide Drilling Components(Drill bits and nozzles)

Tungsten Carbide Compacts for Oil, Gas, Seismic, Mining, Water Well & Geothermal Drilling;

Drill Bit Inserts, Buttons, Grips, Drag Bit Profiles, Gage Blocks, Nozzles, Chips etc。In the relentless search for new sources of energy, whether hydrocarbon-based or carbon-free geothermal, advanced drilling technology makes possible their discovery and utilization. High performance SPP tungsten carbide inserts, buttons, gage blocks and drag bit profiles are hard at work every day in drill bits around the world probing the earth's crust for oil, natural gas, geothermal energy, in seismic drilling, in mining exploration and production and drilling water wells for homes and communities.

SPP CARBIDE offers a full range of sintered tungsten carbide drill bit components for hard and soft formation drilling and boring equipment.

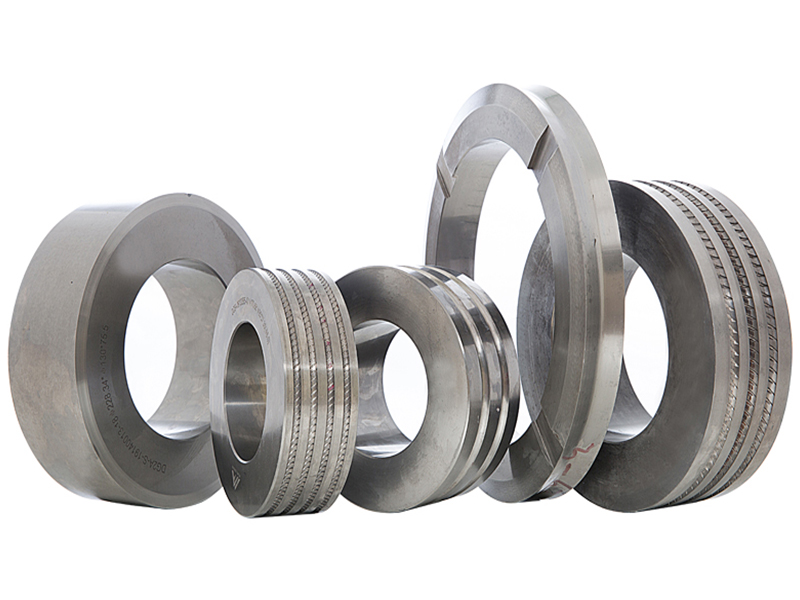

Cemented Carbide Tools for Hot Rolling

Cemented Carbide Tools for Hot Rolling - SPP CARBIDE Manufacturer

The company has 30 years of experience in the manufacture of hot and cold rolling replacement parts, supplying tungsten carbide, carbide, technical ceramics, hardened steel replacement parts and tooling to renowned Chinese and European steel, wire rod and tube manufacturers.

Typical Products:

Rod and Coil Rolling Mill Rolls Rings

Tungsten Carbide Rolls

Wire Guide Wheels

Torsion Rolls

Tilt Rollers

Cooling Nozzles

Inlet and outlet wire guides

Cemented Carbide Compoite Roll

Three Carbide Rings

HSS Rolls, etc.