Cemented Carbide Valve Balls

Ball

As the core component of the ball valve, the ball plays a decisive role in the quality and stability of the ball valve and its service life, our company has been supplying ball products for more than ten years to ball valve manufacturers, and the stable quality has been widely praised.Technical parameters:

Specification: diameter 1/4″~8″

Structure: L-type, T-type, V-type, X-type, hollow sphere, etc.

Pressure: Class150-900

Base material: tungsten carbide, technical ceramics, A105, F304, F316, F316L, etc.

Surface treatment: Electroless nickel plating (ENP), tungsten carbide (TCC), Stearic carbide (STL), Inconel, etc.

In addition to standard parts we also manufacture valve balls according to customer drawings.Cemented Carbide Wear Parts & Tooling manufacturers

Carbide wear parts are adapted to a variety of high strength, high wear resistance working conditions, the company customised carbide tools according to customer drawings.

Cemented carbide has high finish, high hardness and high brittleness, so whatever your requirements, the company can sinter the appropriate carbide grade.Ceramic & Tungsten Carbide Coated Components Machning

Service for ceramic coated parts and tungsten carbide coated parts

-Ceramic coated shafts

-Tungsten carbide coated shafts

-Ceramic coated parts

-Tungsten carbide coated parts

-Ceramic coated bushings

-Tungsten carbide coated wear partsCheck Valve Poppet and Hydraulic Spool Valve Machining

Dongguan spp industry Co.,Limited is a professional manufacturer of hydraulic components, we provide OEM service for high precision check valve poppet and hydraulic spool valve, sleeve, ball cage sleeve, poppet valve, adapter, manifold, hydraulic cylinder components, cylinder block, cylinder sleeve and other components.

CNC Machining Manufacturers

SPP INDUSTRY was one of the first CNC machining manufacturers in China and we are proud to offer a precision core component customisation service to the Chinese industrial sector.We offer a wide range of CNC machining services including 5-axis machining, high speed CNC milling, hard turning, gantry milling, large scale CNC machining, Swiss turning, automatic turning and more.

--CNC machined stainless steel

-Metal machining

-CNC machining of metal parts

-CNC machining of aluminium alloys

-CNC machined titanium

-CNC machined copper

-CNC machining of large parts

-CNC machining of plastic parts

-CNC machining of hardened steel parts

-CNC machining of tungsten carbide parts

-CNC machining of technical ceramic parts

-CNC machining of ruby and sapphire parts

-CNC machining of glass parts

-CNC machining of high-temperature alloysCNC milling manufacturing

We offer a wide range of CNC machining services, including CNC turning, CNC milling, 5-axis machining, hard turning and more.

Cold And Hot Forging Tools & Cutting Knives

Cold And Hot Forging Tooling

Tools in this category can be:

Cutting knives

Cutting dies

Pre shapers / Pre compressors

Final shapers

Shapers

Compacting dies

Forging dies

Conic dies

Reducer dies

Steel & Hard Metal Tools:

Drawing Dies

Drawing Mandrels

Cold And Hot Forging Tools

Rolling Tools

Special Hard Metal ToolsCutting and trimming dies

Stamping dies

Cold heading dies

Reduction / extrusion dies

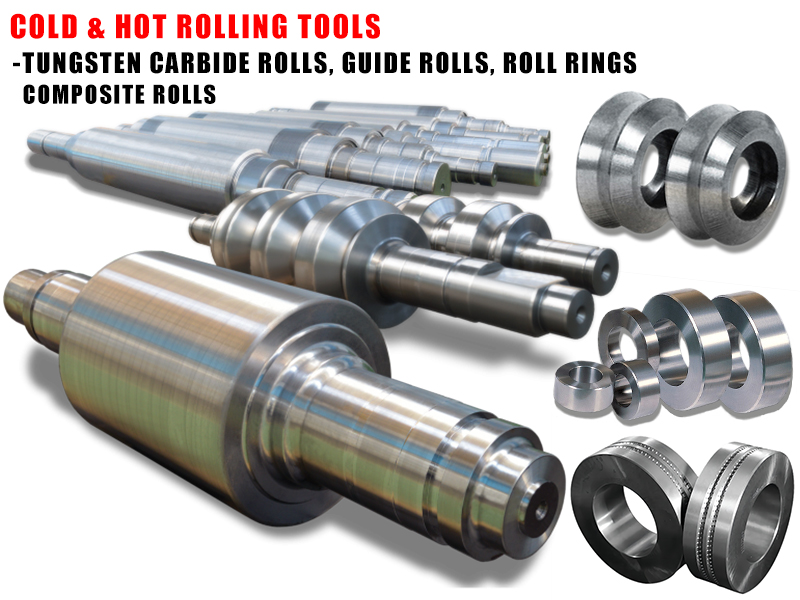

PunchesCold and Hot Rolling Tools-Tungsten Carbide Rolls

SPP CNC MACHINING has been researching, developing and producing tungsten carbide rolls and HSS rolls since 1994. We have patents for a number of products such as tungsten carbide rolls, casting rolls, HSS rolls, roll rings, composite rolls, guides, inserts, wide-band work rolls, forged steel rolls, arbor rods and drums, and mill rolls. We mainly serve with the fields of steel manufacturing, wire rod manufacturing, pipe manufacturing, cold rolling and hot rolling technology, mill manufacturing, etc.

Cold Forming Tooling and Cold Forging Die

Cold Heading Tooling includes:

Carbide and Steel Inserts

Extruding Dies

Taptite ® Inserts

Torx ® and Torx Plus ® inserts

Strux ® Tooling

Magform ® Tooling

Die Cases and Punch Cases

Sleeves

Trim Dies

Cut Off Knives

Quills

Nut Forming Tooling

Knock out pins

Punches

Steel and Carbide Extrusion Pins

Feed Rolls

Prototypes

Machine Parts

Wear Coatings

Carbide DIES

Carbide PVD coated punches

Shaping Dies

Tungsten Carbide Inserts

Taptite

Taptite 2000

T Tap

Torx

Torx Plus

RemincCold Heading Tooling And Cold Forming Tooling

For 50 years, SPP CARBIDE has earned a reputation for producing the highest quality cold heading dies and cold forming dies as well as reliable service and providing the best value for our customers.

We are able to achieve this because of the experience of our talented machinists and because we use state-of-the-art 2-5 axis multi-axis lathes and milling machines in our in-house grinding department and automation in areas such as our wire cutting and stamping EDM departments to produce tools and parts to tight tolerances at competitive prices.

Custom Crankshafts Manufacturers

The company is a professional OEM crankshaft manufacturer, we customize crankshafts, camshafts and eccentric shafts according to drawings and finish them by high precision crankshaft grinding.

The company manufactures crankshafts for a wide range of applications in the automotive, motorbike, outboard, light aircraft, compressor, engine, off-road vehicle, sled, garden machinery, agricultural machinery and industrial machinery industries.Custom Eccentric Shafts for Rotor Engines

We manufacture eccentric shafts for rotor engines that are ground to a high degree of precision for crankshafts and mirror polishing services to a surface Ra of 0.01um, resulting in ultra-high strength wear resistance and durable function, one of our patented products.