Disc Stack and Valve Cage for Fluid Control

Tungsten carbide tools for oil, gas and petrochemical applications:

Tungsten carbide has been used in flow control technology for many years. The reason: onshore as well as offshore, we often encounter extreme conditions. Moisture, sand and abrasive solids can cause tremendous wear - not only downstream, but in all phases of upstream processing operations after extraction. For many years, SPP CARBIDE has been a leader in offshore technology, exploration technology, mining technology, fluid control technology, hydraulics and pump body technology, drilling technology, power generation and environmental protection, where tungsten carbide and technical ceramics are becoming increasingly important.products:

Valve inserts, radial bearing sleeves, pistons, complex construction parts for extreme applicationstypical applications:

Drill drives, choke valves, control valves, shut-off valves, processing systems, onshore, offshoreEMD Machining Mold Parts for Headphone Manufacturing

We supply precision components according to drawings for the field of acoustic system tooling and tool manufacture, they are machined by EDM and WEDM.

Engine Crankshaft Manufacturing

The company has been specializing in engine crankshafts for decades and we have set up a special machinery park in Chongqing for manufacturing crankshafts, eccentric shafts, camshafts, cams and other components.

Engine crankshaft application areas:

-Automotive Engines

-Tractors

-Stationary Engines

-Industrial Engines

-Locomotives

-Marine Engines

-Large Commercial Vehicle and New Energy Vehicle Engines

-Rotor engines and light aircraft engines

-Electric Motors

-Agricultural Machinery

-Engines for off-road vehicles, sleds, racing cars, motorcycles, etc.

-Construction machinery, earth rammer crankshaft

-Garden machinery engines, etc.Engineering Eccentric Shafts Machining

The company is one of the largest manufacturers of eccentric shafts, crankshafts, camshafts and cams in China. In our 24,000m2 precision grinding machinery park, we offer the full range of processes from forging to CNC machining to precision non-circular grinding.

Eccentric shafts are generally finished from hardened steel such as tool steel or nitrided steel. We can control the eccentric distance tolerance to around 0.004 and grind the finish to Ra 0.01um, which can better ensure the durability of the eccentric shaft.ESP Components & Tungsten Carbide Sleeves and Bushings

Bushing & Sleeve of ESPThe cemented carbide bushing & sleeve will mainly be used on electric submersible pump(ESP) in oil field. There are kinds of sleeves, such as normal cylindrical axle sleeve, cylindrical axle sleeve with slot, axle sleeve with convex stage, axle sleeve with slot and convex stage, non-standard axle sleeve etc. There is a big choice of sizes and types of products. We can also recommend, design, develop, produce and supply the products according to the drawings and requirements of customers. Five-axis CNC Machining of Die Plates & Sets

SPP INDUSTRY is a professional Die Plates & Sets manufacturer and supplier, we provide precision 5 axis CNC milling, 5 axis machining centre, 5 axis gantry machining centre services for Die Plates & Sets for tooling and tooling.

Flow Carbide Cages for Oil Industries and Throttle Valves

SPP Carbide product range for oil and gas production includes artificial lift, flow control, and fluid end components manufactured from hard materials as well as specialty steels designed to improve the performance and extend the life of our customers’ products. From simple, straight walled choke beans to products with complex geometries used in ESP pumps. SPP Carbide supplies high-quality materials and components that have made us a leading supplier in this market segment.

The components include cages, sleeves, seats, points, rings, and discs for different design valves.

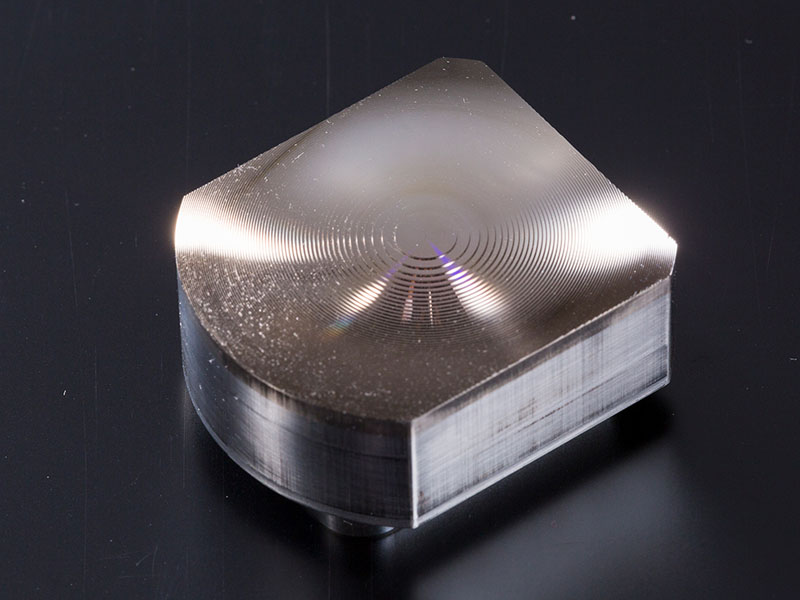

Fresnel Lenses Machining for Optical Tooling Components

Advantages of Precision Machined and Custom Fresnel Lenses and Fresnel Lenses.

Physically, the Fresnel lens has a narrow profile that focuses light similar to a conventional optical lens, but has several advantages over its thicker counterparts:

Light weight: a very interesting option in situations where weight is important (automotive, aerospace, etc.);

Large format: Fresnel lenses are very useful for standard and wide-angle applications;

Various substrate materials: substrate materials vary from acrylic to polycarbonate and glass.

Performance: excellent light gathering capability.Glass Lens Tooling Forming Moulds and Die Kernels

We are a manufacturer of moulds for the forming of optical components (lenses). Optical lens moulds generally require a very rigorous mirror polishing of the die insert, cavities, cores and inserts.

We support high precision mirror polishing services, not only on carbide materials but also on stainless steel, tool steel and aluminium alloys.

High Precision Centreless Grinding Services Manufacturer

We offer a high precision centreless grinding service with an accuracy of up to 0.001. Centreless grinding guarantees the true roundness and concentricity of the components and is therefore very suitable for the manufacture of ancillary components.

For example:

-Hydraulic components

-Hydraulic spools and sleeves

-Valve stems

-Tungsten carbide fluid components

-Technical ceramic pin gauges

-Gauges and gauges

-Technical ceramic rods etc.High Precision Internal & External Grinding Service

High precision internal & external cylindrical grinding service with honing, co-ordinate grinding, profiling, non-circular grinding and crankshaft grinding services.

Typical ground parts:

-Spindle and bushings

-Shaft components

-Gears

-Tungsten carbide components

-Technical ceramic components

-Eccentric shafts and camshafts

-Crankshafts

-Cam

-Nozzles

-Die components

-Hydraulic spool and sleeve

-Pump body components etc.

的模具.jpg)