OEM/ODM Punches and IC Die Pins for Semiconductors

Precision stamping die components are used in the semiconductor field. Punches and IC die pins are finished with tungsten carbide or hardened tool steel, and additional PVD coating services are also available. SPP INDUSTRY's die components are 6 times more durable than ordinary die standard parts, which is one of our patented products.

Oil And Natural Gas Wear Parts Manufacturers

Oil and gas tungsten carbide wear parts

Major oil and gas companies rely on us for tungsten carbide drilling parts, probing parts, remote control parts, ceramic pump parts, hardened tool steel wear parts, M.W.D and L.W.D parts, and many other specialized oil wear parts.Our excellent service, experienced personnel and well-trained machinists have given us an excellent reputation in many industries. Our reliable delivery and competitive pricing, along with our quality assurance and on-time delivery programs, have enabled us to maintain and grow our customer base in the oil and gas industry.

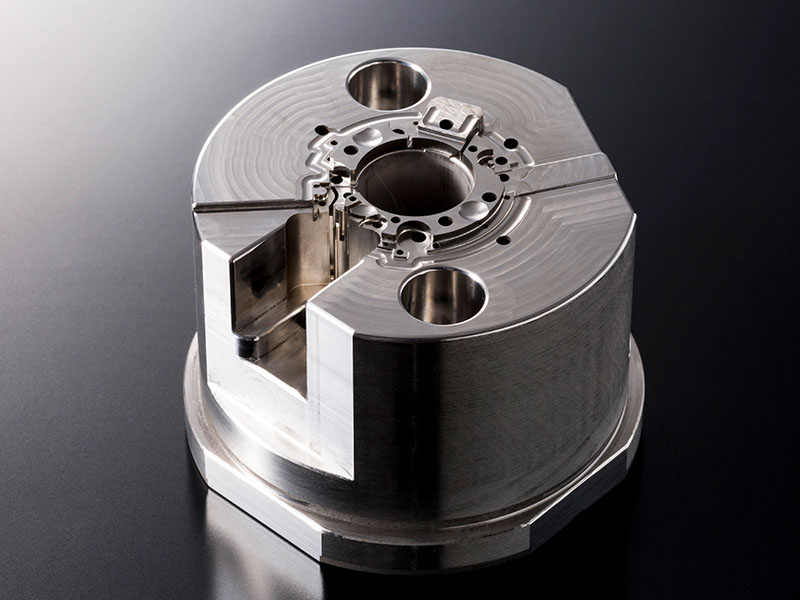

Optical Component Mould Insert Manufacturer

Optical component mould insert manufacturer

Optical Mould Components and Tooling Inserts

Manufacturer of precision inserts and cavities, we manufacture components such as mould inserts and cavities, die kernels and cores, slides and core pins for the manufacture of optical components from drawings.

Optical Mould Components For Car Reflectors Tooling

The finished surface of high precision reflector moulds requires high angular accuracy and a mirror polish. The OEM of precision optical mould components is a successor business to SPP INDUSTRY. The company's technology is also effectively applied in reflector moulds. Mould cores and inserts for 3D curved reflectors such as automotive tail lights are formed by electroforming from a pin-mounted master mould. A tell-tale five-axis milling service and mirror polishing is also available, which can be finished to Ra 0.01µm (slope or flatness)

Outboard Crankshaft Manufacturers

We offer OEM and ODM services for outboard crankshafts and other outboard motor engine components such as crankshafts, eccentric shafts or camshafts customized from drawings.

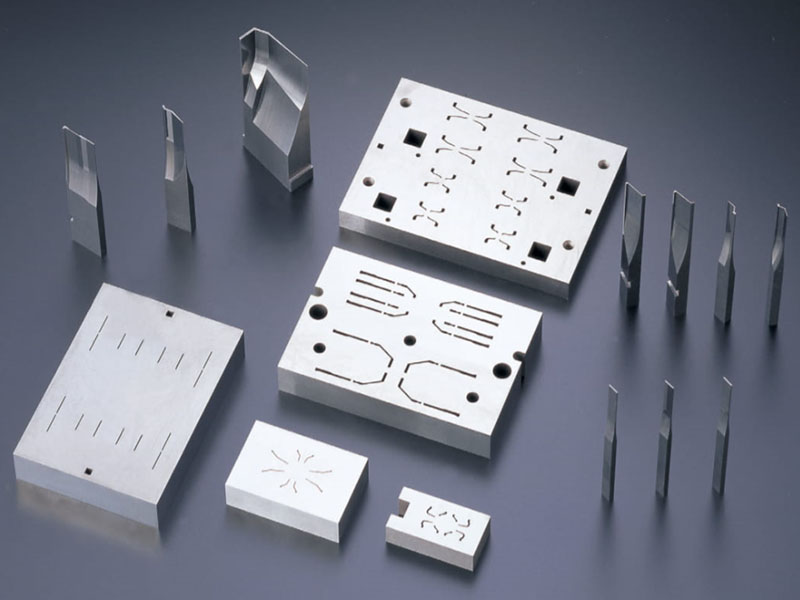

Pot & Plunge for Semiconductor Packaging Tooling

We supply mould components for semiconductor packaging, integrated circuits, they are completed with carbide, technical ceramics, hardened tool steel.

Typical products:

Strip Cavity

Pot & Plunger

Ejector Pins

Cavity QFP

Cavity - T2R

Cavity - SFLAT

Cavity - QFN

Cavity - ESOP

Tungsten Carbide Speciality Inserts

Mould Inserts

Punch & Matrix

Guidance elements, etc.Pot,Plunger, Gate Insert for Semiconductor Dies

We have customized IC die pins for semiconductor test equipment (IC testers) and our highest priority is to provide our customers with comprehensive technical, engineering and manufacturing support for all your connection needs.

We also offer the widest range of suction cups for your automation solutions. Including custom suction cups to fit your specific application.

-pot, plunger

-gate insert

-punches and pins

Powdered Metal Compaction Tooling & Sintering Tooling

Powdered Metal Compaction Prees Tooling & Sintering Tooling & Carbide Dies

SINTERING TOOLINGThe construction of dies and punches for the sintering of metal powders requires equipment of high accuracy, repeatability and autonomy. SPP CARBIDE DIE is not only equipped with these mentioned methods, but also adapted them automated and robotic.

This makes it one of the best companies in the world for the production of tools for pressing, sintering and shaping of metal powders.SPP CARBIDE DIE has modern high speed machining centers and Swiss wire spark machines and Swiss EMDs for machining complex frontal contours of upper and lower punches with hardnesses ranging from 60-64 HRc after heat treatment.SPP CARBIDE DIE has also developed different grades of Carbide DIE has also developed different grades of carbide punches.

Precision Cam Manufacturing Cam Grinding Service

The cam manufacturing service uses specialised equipment, such as machining and turning centres under CNC computer control, to produce cams to customer specifications. The manufacturing process is capable of producing a wide range of pieces, from small detailed parts to large castings. Cams can be made from a variety of materials including high temperature alloys such as nickel and titanium alloys. The cam manufacturing service can update old cam data and provide cam designs (manufacturing output files and/or master cams) as required.

Precision CNC Turning and Eccentric Turning

We offer a wide range of CNC machining services, including CNC turning, CNC milling, 5-axis machining, hard turning and more.

Precision Machinery & Industrial Parts CNC Machining

We manufacture precision mechanical and industrial hardware parts from drawings in stainless steel, aluminium alloys, brass, tool steel, hardened steel, technical ceramics, tungsten carbide, titanium, nickel, high temperature alloys, etc.

We offer precision CNC machining, CNC turning, CNC milling, CNC Swiss turning, CNC drilling, CNC flat milling, CNC thread manufacturing and more.